The Core Function of NC Press Brake Machines

In the world of sheet metal fabrication, the NC press brake machine plays a pivotal role in achieving precise bending and shaping of materials. Unlike conventional mechanical presses, NC (Numerical Control) technology enables operators to program bending sequences and angles directly, which ensures consistency and accuracy across production batches. This capability reduces human error and allows for the processing of complex bending patterns with high efficiency. In industries where even minor deviations can compromise product quality, the precision of an NC press brake machine is indispensable.

Design Features That Enhance Performance

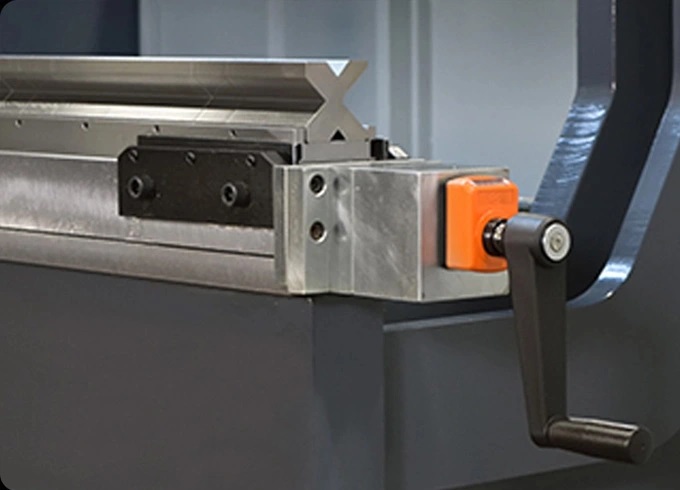

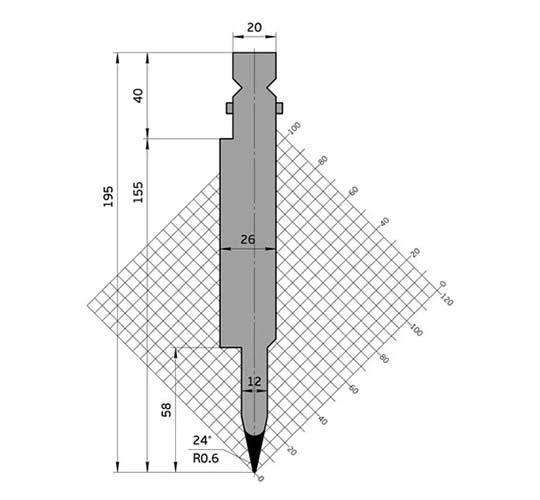

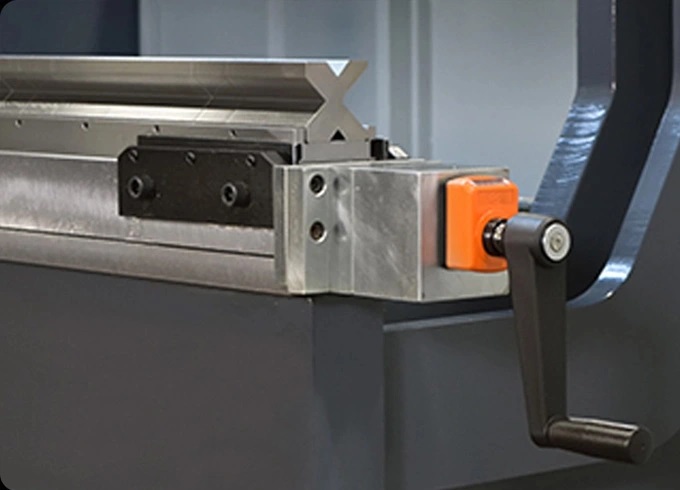

One of the defining features of an NC press brake machine is its programmable control system. By integrating advanced controllers, operators can adjust bending pressure, stroke length, and positioning with ease. This adaptability makes the machine suitable for a wide range of applications, from producing small components with intricate bends to handling large sheet metal panels. Furthermore, the frame design and heavy-duty construction enhance stability, minimizing vibrations and maintaining accuracy even under prolonged workloads. Manufacturers like LANGYE, with extensive experience in developing press machines, focus on building durable structures that can withstand the demands of high-output environments.

Applications Across Different Industries

The versatility of the NC press brake machine makes it a vital tool across numerous industries. In the automotive sector, these machines are used for fabricating body panels, brackets, and support structures. In construction, they contribute to the production of beams, enclosures, and framework elements. Electrical and appliance industries rely on NC press brakes to produce precision housings and components where exact dimensions are critical. The ability to switch quickly between programs also enables businesses to cater to customized requirements, making the machine suitable for both mass production and specialized small-batch manufacturing.

Efficiency, Accuracy, and Cost Reduction

Another reason the NC press brake machine is so highly valued lies in its ability to balance efficiency and accuracy while reducing costs. The automation of bending processes not only shortens production cycles but also decreases material waste. Every programmed bend is executed with uniform precision, lowering the risk of rework or scrap material. By optimizing energy usage and minimizing manual intervention, businesses achieve greater productivity and cost-effectiveness. Over time, the savings generated from reduced errors and faster turnaround make the investment in an NC press brake machine highly worthwhile for manufacturers aiming to scale production without sacrificing quality.

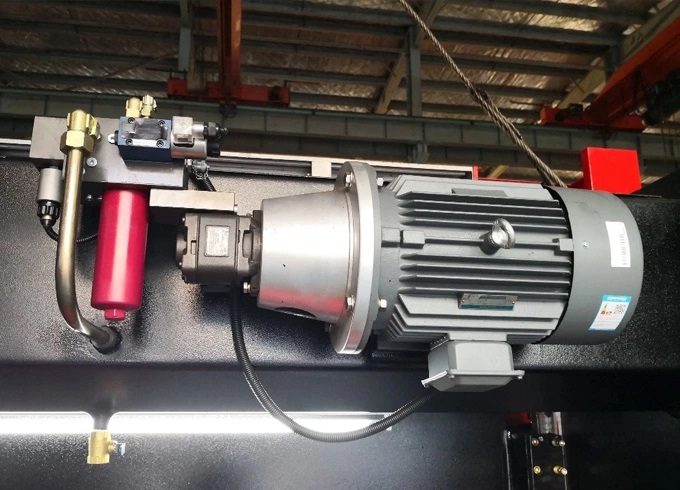

Maintenance and Operational Considerations

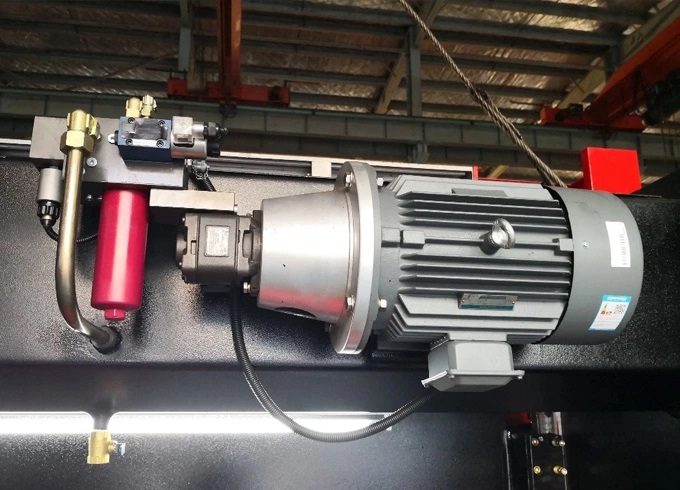

Although the NC press brake machine is designed for durability, regular maintenance is essential to maintain peak performance. Operators should routinely check hydraulic systems, lubrication levels, and alignment settings to prevent mechanical wear. The accuracy of sensors and control units must also be calibrated periodically to ensure precise bending results. Training operators in programming and safe handling is equally important, as improper use can diminish the advantages of the technology. With proper care and skilled operation, an NC press brake machine can deliver consistent high-quality output for many years, supporting businesses in staying competitive in the global manufacturing landscape.

English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español русский

русский Türkçe

Türkçe português

português العربية

العربية Polska

Polska हिंदी

हिंदी Indonesia

Indonesia