Plastic waste management has become a key focus across industries to improve recycling efficiency and reduce environmental impact. In successful plastic recycling operations, the quality of equipment is a crucial factor, especially the plastic shredder blade. In this blog, we will explore the role, applications, importance of quality blades, and whether these blades can be replaced.

What is a Plastic Shredder Blade?

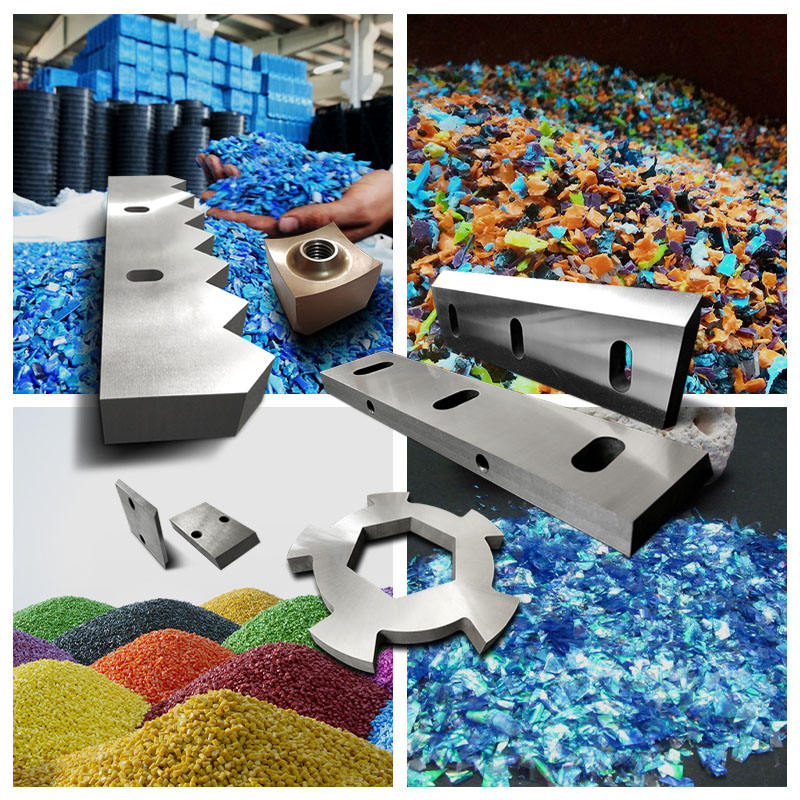

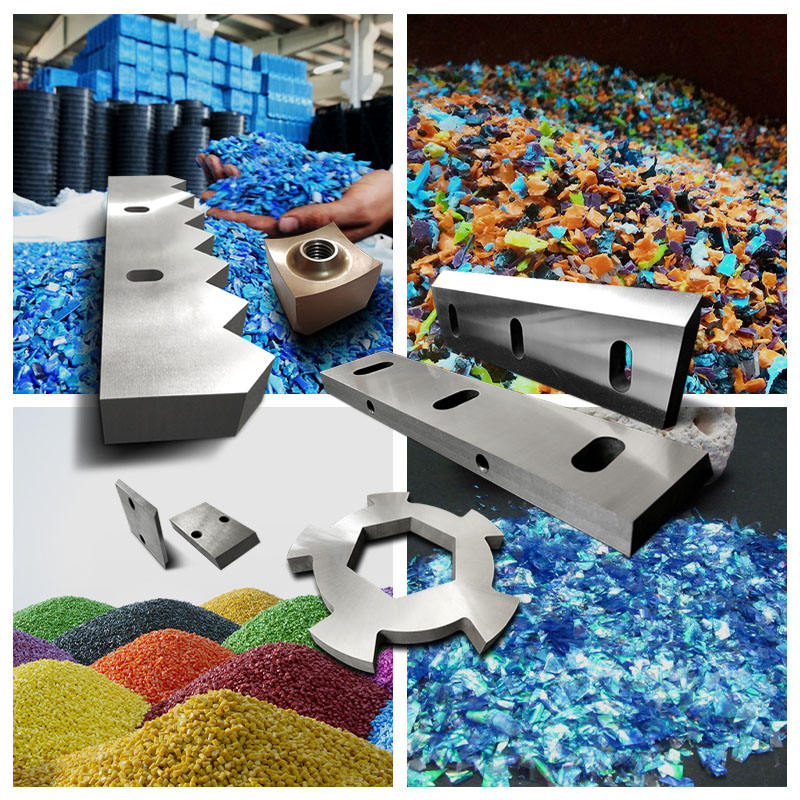

A plastic shredder blade is a specialized tool used in industrial shredders, primarily to cut plastic waste into smaller, manageable particles. This blade is designed for cutting various types of plastics, such as PET, PVC, and HDPE, transforming bulky plastic items into uniform particles, which makes recycling or disposal easier. The plastic shredder blade is usually made from durable materials like high-carbon steel or hardened alloy steel to ensure it can withstand the wear and tear of cutting hard plastic materials over long periods.

Applications of a Plastic Shredder Blade

A plastic shredder blade is widely used across multiple industries. Specific applications include:

| Industry | Application |

|---|

| Recycling Industry | Shredding post-consumer plastic waste for recycling and reuse. |

| Waste Management | Reducing plastic waste, lowering landfill volume, and improving recycling efficiency. |

| Packaging Industry | Shredding plastic packaging materials, such as bottles, containers, and packaging films. |

| Manufacturing Industry | Shredding plastic parts and waste during the production process. |

| Automobile Industry | Recycling plastic parts from old cars for reuse in the production of new components. |

In these industries, plastic shredding plays a vital role in ensuring plastic waste is efficiently processed and sorted, ultimately being transformed into new products or disposed of more sustainably, thereby significantly reducing environmental impact.

Importance of Quality Plastic Shredder Blade in Waste Management

In plastic waste management, the quality of shredder blades for plastic directly influences the efficiency of the shredding process and the longevity of the equipment. Here are a few reasons why high-quality blades are indispensable in waste management:

Durability: High-quality plastic shredder blade is made from durable materials, capable of long-term use even when shredding hard, rigid plastics. This reduces the frequency of blade replacements, thereby lowering overall operational costs.

Efficiency: Quality blades provide clean, effective cuts, minimizing energy consumption as they can cut through plastic more easily, reducing friction. This enhances the performance of recycling facilities, allowing large volumes of waste to be processed more quickly.

Consistent Output: Quality blades ensure more uniform and consistent plastic particles, which is crucial for subsequent recycling processes. Uniform plastic particles are easier to melt, mold, and convert into new products, contributing to a more sustainable recycling cycle.

Reduced Maintenance Costs: High-quality blades typically require less maintenance and repair, which can save companies significant downtime and repair costs. In contrast, frequently replacing low-quality blades can lead to increased maintenance expenses.

Brands like LANGYE are known for producing plastic shredder blade that meets high-quality standards, ensuring superior performance and longevity in waste management.

Can a Plastic Shredder Blade be Replaced?

Yes, a plastic shredder blade can be replaced when it becomes dull or damaged. In fact, regularly replacing blades is crucial to maintaining the efficiency and productivity of the shredder. Over time, the cutting edges of the blade wear down due to continuous use, leading to decreased shredding performance. Timely replacement of the blade ensures that the shredder continues to operate at optimal efficiency.

When replacing a plastic shredder blade, consider the following points:

Compatibility: Ensure the new blade is compatible with your shredder model. Many manufacturers (such as LANGYE) provide detailed specifications to help you choose the right replacement blade.

Material Quality: Choose a high-quality replacement blade made from durable materials to maintain consistent performance. Opting for hardened steel or high-carbon alloy steel blades will ensure their durability.

Regular Maintenance: Regularly inspecting the condition of the blade is crucial. A sharp and well-maintained blade is essential for keeping the plastic shredding process smooth and efficient.

By investing in a quality replacement blade and proper maintenance, businesses can extend the lifespan of shredding equipment, improve recycling efficiency, and reduce operational costs.

Conclusion

The quality of the plastic shredder blade plays a crucial role in the effectiveness and sustainability of plastic waste management systems. High-quality blades contribute to increased efficiency, durability, and overall performance of recycling operations. Whether you are in the waste management, packaging, or recycling industry, ensuring that your plastic shredder blade meets standards will play an important role in improving environmental impact and operational efficiency. Brands like LANGYE help your operations run more smoothly and extend equipment lifespan by providing high-quality plastic shredder blade.

By understanding the importance of this blade and properly maintaining or replacing it when necessary, you can ensure that plastic shredding equipment continues to operate efficiently and contribute to a cleaner, more sustainable future.

English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español русский

русский Türkçe

Türkçe português

português العربية

العربية Polska

Polska हिंदी

हिंदी Indonesia

Indonesia