In the scrap metal recycling industry, choosing the right shredder can make or break operational efficiency. Double-shaft shredders and single-shaft shredders each have unique strengths, but when it comes to processing tough, bulky metal waste like end-of-life vehicles or scrap cars, double-shaft shredders stand out for their high throughput and minimal pre-processing needs. By leveraging two intermeshing shafts with powerful blades, these machines excel at shearing and crushing challenging materials. This blog explores the key differences between double-shaft and single-shaft shredders, highlighting why double-shaft models are often the preferred choice for scrap metal processing.

What are Single-Shaft Shredders

Single-shaft shredders are designed for precision and flexibility, making them suitable for specific recycling applications. These machines use a single rotating shaft with blades and often incorporate sizing screens to produce uniform particle sizes, which is ideal for processes requiring consistent material output. Their variable speed settings allow operators to adjust performance based on the material being shredded, offering adaptability for lighter or less complex tasks. Maintenance for single-shaft shredders tends to be more frequent but involves shorter intervals and less expensive consumable parts. However, these shredders may struggle with heavy-duty or bulky materials, often requiring more pre-processing or sorting of scrap metal. This makes them better suited for lower to medium volumes, where precision is prioritized over raw power.

What are Double-Shaft Shredders

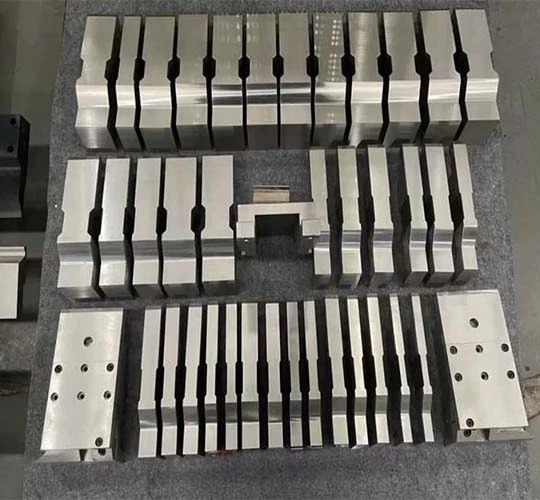

Double-shaft shredders are built for heavy-duty performance, featuring two intermeshing shafts with high-torque motors that efficiently shear and crush tough, bulky materials. Their robust design allows them to process large volumes of scrap metal, such as end-of-life vehicles, tires, and heavy-duty plastics, with minimal pre-processing. This efficiency reduces setup time and labor costs, making them ideal for high-throughput operations. Double-shaft shredders are also highly reliable, capable of handling contaminants like tramp metal without compromising performance, which enhances their durability in challenging environments. While they may produce less uniform particle sizes compared to single-shaft models and come with a higher initial cost, their ability to tackle a wide range of materials and large volumes makes them a powerhouse in scrap metal processing.

Comparing Applications and Performance

The choice between single-shaft and double-shaft shredders depends on the specific demands of the recycling operation. Single-shaft shredders shine in applications where precise particle size is critical, such as processing lighter materials or preparing scrap for downstream processes that require uniformity. Their flexibility and lower-cost maintenance make them a good fit for smaller-scale operations or materials that don’t require heavy-duty processing. In contrast, double-shaft shredders are the go-to choice for scrap metal recycling, where tough, bulky materials and high volumes are common. Their high torque, large capacity, and ability to handle contaminants make them ideal for processing complex metal waste, such as automotive scrap or industrial byproducts, with minimal preparation.

Why Double-Shaft Shredders Excel in Scrap Metal Processing

For scrap metal processing, double-shaft shredders offer clear advantages. Their ability to handle tougher materials with high throughput reduces the need for extensive pre-processing, saving time and labor. The robust design ensures reliability even in demanding environments, making them suitable for processing a variety of metal waste, from scrap cars to heavy-duty plastics. While the initial investment may be higher, the efficiency and versatility of double-shaft shredders lead to long-term cost savings by streamlining operations and reducing downtime. For applications requiring precision particle sizes, single-shaft shredders may be more appropriate, but for the rugged demands of scrap metal recycling, double-shaft models are unmatched.

Double-shaft shredders are the preferred choice for scrap metal processing due to their ability to efficiently handle tough, bulky materials with high throughput and minimal pre-processing. While single-shaft shredders offer precision and flexibility for lighter materials or applications requiring uniform particle sizes, they fall short in heavy-duty scenarios. By investing in a double-shaft shredder, recyclers can boost productivity, enhance reliability, and tackle a wide range of materials with ease. For businesses in the scrap metal industry, choosing a double-shaft shredder is a strategic decision that drives efficiency and ensures long-term success in a competitive market.

English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español русский

русский Türkçe

Türkçe português

português العربية

العربية Polska

Polska हिंदी

हिंदी Indonesia

Indonesia