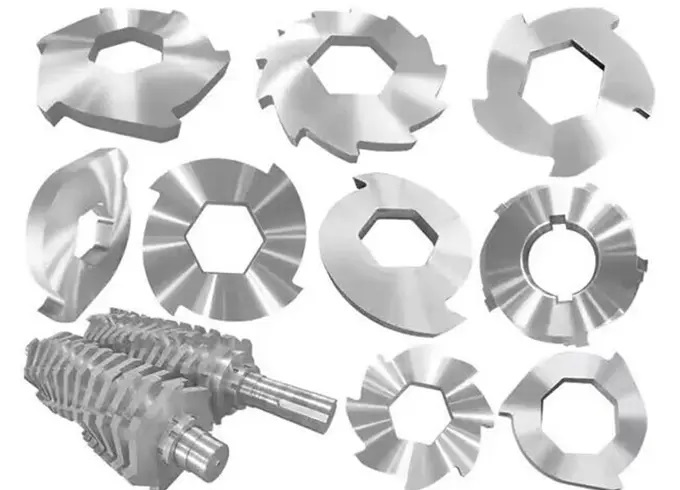

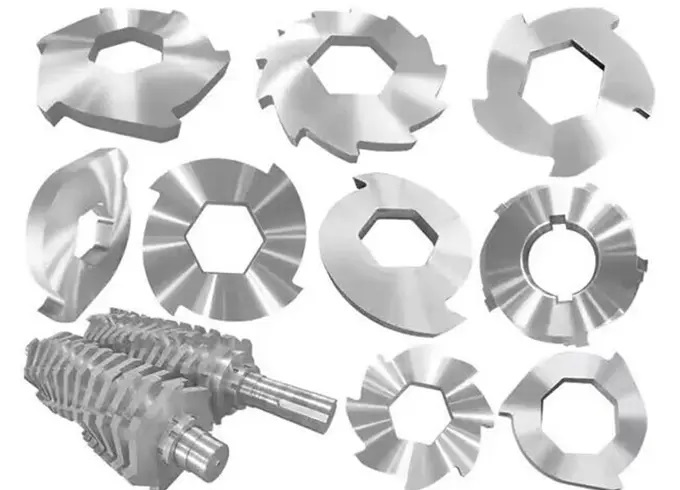

Material Composition and Durability

When evaluating the quality of double shaft shredder blades, the first factor to consider is the material. High-quality blades are typically made from alloy steel or other wear-resistant metals designed to withstand continuous friction and high impact. The blade’s ability to resist abrasion and deformation directly determines its durability. If the blades are manufactured with inferior steel or without proper heat treatment, they will dull quickly, leading to reduced efficiency and higher maintenance costs. Companies like LANGYE, with advanced heat treatment furnaces and heavy-duty machining platforms, ensure that each blade undergoes rigorous processing to achieve a hardness balance between sharpness and toughness.

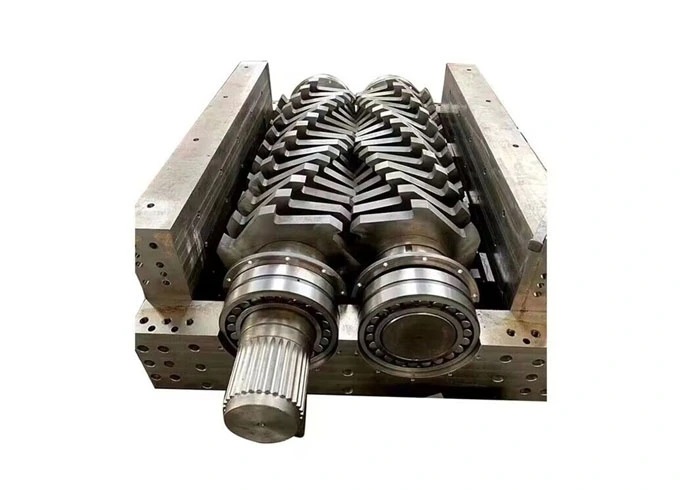

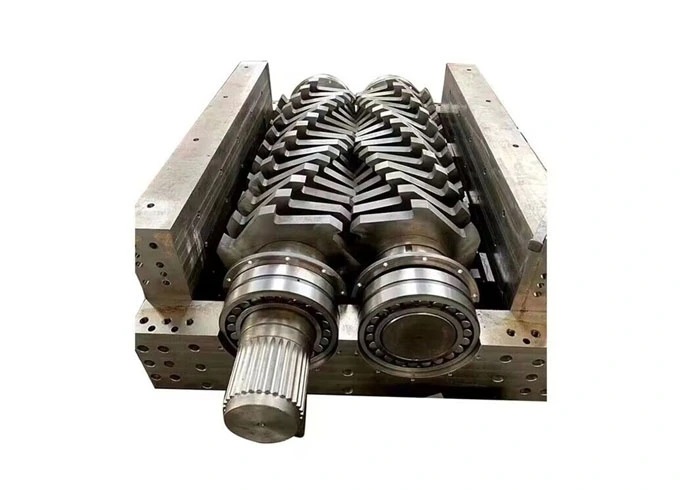

Precision in Manufacturing

Another important aspect of blade quality lies in the precision of its manufacturing process. High-performing double shaft shredder blades require exact cutting angles and consistent thickness to deliver clean, uniform shredding results. Even slight deviations in blade dimensions can lead to uneven material feeding, increased vibration, and premature wear. By using pentahedral drilling machines and CNC machining centers, precision levels can be achieved that guarantee blade alignment and cutting accuracy. This precision ensures that every shred cycle is efficient, reducing downtime and energy consumption.

Sharpness and Edge Retention

The sharpness of double shaft shredder blades and their ability to retain that sharpness over long periods are crucial indicators of quality. Blades should maintain their cutting edges even when processing tough materials like plastics, rubber, wood, or metal scraps. High-quality blades not only start sharp but are also engineered to resist chipping and cracking under extreme loads. Proper blade geometry, including the right cutting angle, allows them to slice through material with minimal resistance. Regular inspections should show a consistent edge profile without excessive rounding or deformation, which reflects superior craftsmanship from reliable manufacturers.

Heat Treatment and Hardness Balance

Heat treatment is one of the most decisive factors in blade quality. Properly treated double shaft shredder blades achieve the optimal balance between hardness and toughness. Blades that are too hard may break under heavy loads, while blades that are too soft will wear out quickly. Advanced heat treatment techniques, such as those employed by LANGYE, allow for deeper penetration of hardness throughout the blade’s cross-section, improving resistance to both wear and impact. Consistency in hardness across the entire blade ensures uniform performance, minimizing the risk of sudden failure during shredding operations.

Maintenance, Lifespan, and Replacement Frequency

The overall quality of double shaft shredder blades can also be measured by their lifespan and the frequency with which they need to be replaced. High-quality blades deliver longer operational hours before requiring sharpening or replacement, lowering long-term costs. Easy maintenance is another sign of good design, as blades should allow for convenient installation, adjustment, and replacement. Partnering with established suppliers like LANGYE means access to blades that are engineered for reliability, efficiency, and minimal downtime, making them an optimal choice for industrial shredding operations.

English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español русский

русский Türkçe

Türkçe português

português العربية

العربية Polska

Polska हिंदी

हिंदी Indonesia

Indonesia