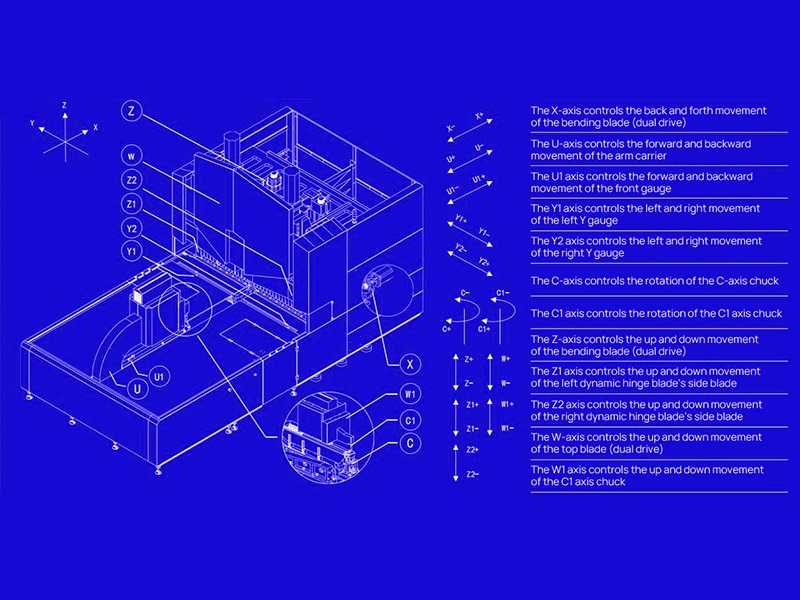

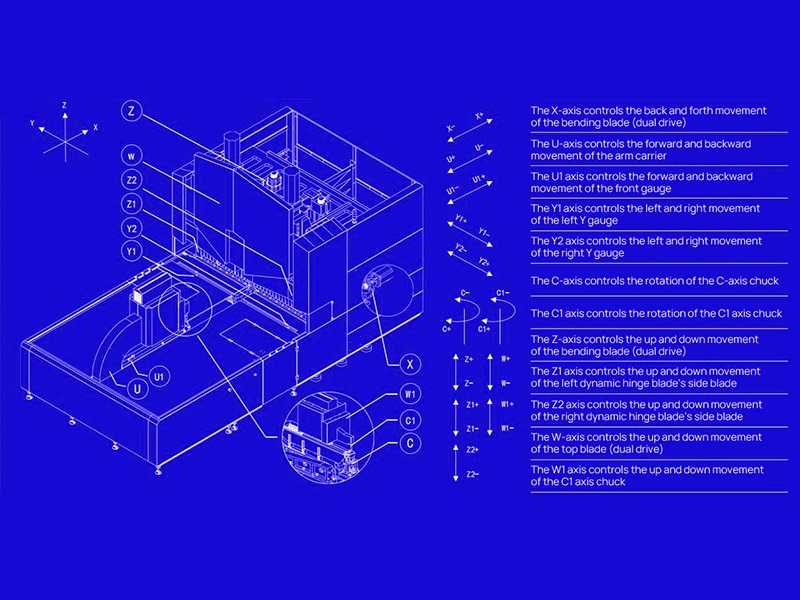

Understanding CNC Panel Bender Before Operation

A CNC panel bender is a precision machine used for bending sheet metal into complex shapes with accuracy and efficiency. Compared with traditional bending machines, it integrates automated programming and servo control systems, reducing manual intervention and ensuring consistent results. Before using such equipment, operators need to have a clear understanding of the machine’s functions, software interface, and bending sequence design. Misunderstanding the programming or ignoring the bending radius can lead to product deformation or excessive material stress. For new users, it is essential to undergo professional training and familiarize themselves with how panel bender manufacturers like LANGYE design safety protocols and performance parameters for these machines.

Preparing Materials and Tools Correctly

One of the most important precautions when working with a CNC panel bender is ensuring that materials and tools are properly prepared. The thickness, hardness, and coating of the sheet metal directly influence the bending angle and precision. Using incorrect materials or failing to inspect them for scratches and impurities may result in inaccurate bends or surface damage. Additionally, the bending tools and dies must be checked carefully before each production run. Panel bender manufacturers often provide compatible tool sets optimized for different sheet thicknesses and metals, and ignoring these recommendations can shorten tool life and compromise product quality. Proper lubrication and alignment of the machine also play a crucial role in preventing unnecessary wear.

Safety Considerations During Operation

Safety is always a priority in metalworking, and CNC technology does not eliminate the need for careful monitoring. When using a CNC panel bender, operators must follow strict safety rules such as keeping hands away from moving components and never attempting to adjust tools while the machine is running. Modern systems include sensors and protective barriers, but human vigilance remains key. Operators should wear appropriate protective gear, including gloves and goggles, to guard against sharp sheet edges and potential debris. Emergency stop buttons and protective shields are standard features provided by reliable panel bender manufacturers, but they are effective only if users remain attentive and test them regularly before production begins.

Maintenance and Calibration for Long-Term Reliability

Another essential aspect of safe and efficient usage is machine maintenance. A CNC panel bender requires routine cleaning of the working area to remove dust, metal shavings, and oil residues. Regular calibration ensures that the bending angle, pressure, and tool alignment remain precise. Neglecting maintenance may cause deviations in the final product and even mechanical failures. Panel bender manufacturers typically recommend scheduled servicing, which may include checking hydraulic systems, verifying software updates, and replacing worn-out parts. Keeping a maintenance log is also a best practice, as it allows operators to track the performance of the equipment and anticipate potential issues before they become major problems.

Optimizing Productivity Without Compromising Quality

When operating a CNC panel bender, users often aim to increase production speed while maintaining accuracy. However, pushing the machine beyond its recommended capacity can lead to premature wear or inconsistent results. To optimize productivity, operators should use the automation functions wisely, such as programming sequences that minimize tool changes and material repositioning. Working closely with panel bender manufacturers can provide valuable insights into best practices for improving efficiency while safeguarding equipment longevity. In addition, careful monitoring of the first production samples ensures that adjustments can be made early, avoiding costly errors during large-scale runs.

English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español русский

русский Türkçe

Türkçe português

português العربية

العربية Polska

Polska हिंदी

हिंदी Indonesia

Indonesia