Selecting the appropriate plate rolling machine is a critical decision for manufacturers in metal fabrication, as it directly impacts productivity, precision, and cost-effectiveness. This guide provides a structured approach to choosing a plate rolling machine by outlining the importance of understanding specific needs, gaining knowledge about machine types, evaluating manufacturers, and considering key factors like quality, price, and service. By following these steps, buyers can make informed decisions to acquire equipment that aligns with their operational requirements.

Defining Needs and Requirements

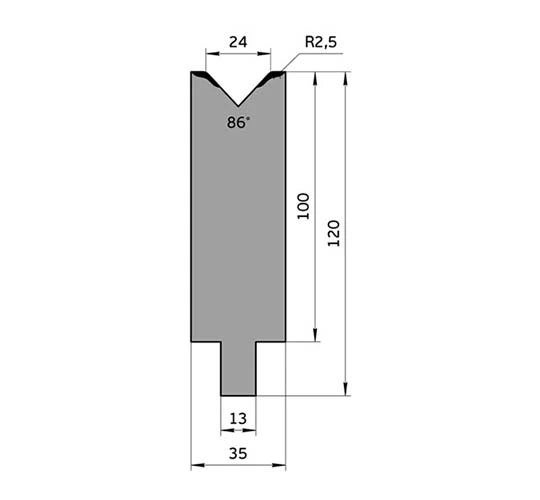

To choose the right plate rolling machine, it's essential to clearly define the specific needs of the project. This involves identifying the parameters of the plate, such as its material, thickness, and width, which determine the machine's required capacity. Additionally, processing requirements, including workpiece shape, roll diameter, precision, roundness, allowable error, angle, opening size, and any special features, must be considered. Providing accurate and detailed information to manufacturers or suppliers enables them to recommend the most suitable model and provide a precise quotation tailored to the application. Clear communication of these requirements ensures the selected machine meets production goals effectively.

Understanding Plate Rolling Machines

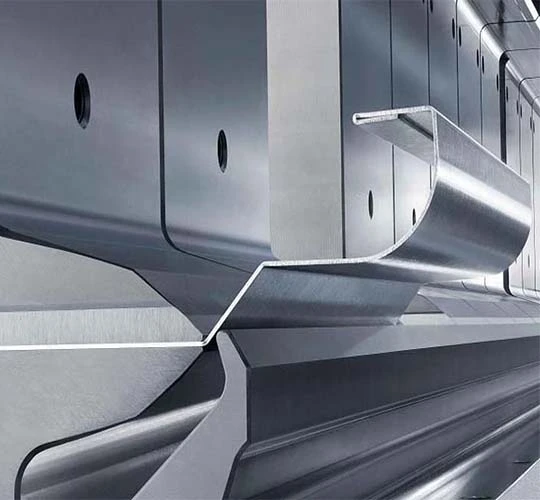

A basic understanding of plate rolling machines enhances communication with manufacturers and aids in selecting the best equipment. Key considerations include the type of drive system—hydraulic or mechanical—and the number of rolls, which can be two, three, or four. Additionally, the control system, whether manual, numerical control (NC), or computer numerical control (CNC), impacts precision and ease of operation. For instance, three-roll machines are suitable for steel or metal sheets of varying thicknesses and are generally more cost-effective than four-roll models, which offer higher precision, efficiency, and capacity. Four-roll CNC machines can bend plate ends directly without additional equipment, minimizing straight-edge length, while asymmetrical three-roll machines require plate turning, but four-roll models simplify the process, improving efficiency and reducing labor intensity. Consulting professionals or researching these aspects ensures a better grasp of the machine's capabilities and suitability for specific tasks.

Evaluating Manufacturers and Machine Details

Choosing a reliable manufacturer is crucial for acquiring a high-quality plate rolling machine. Several factors should be assessed to ensure the selected equipment meets performance and durability standards, including quality, price, and service. By carefully evaluating these aspects, buyers can secure a machine that offers long-term value and reliability.

Assessing Machine Quality

The quality of a plate rolling machine is paramount, as it determines performance and longevity. Evaluating quality involves examining the frame's strength, the machine's appearance, its application range, rolling accuracy, speed, special functions, control complexity, operational stability, failure rate, repair frequency, and service life. The configuration of critical components, such as the reducer, motor, and rollers (whether hollow or solid), significantly affects durability. Asking specific questions about the machine's weight, component brands, and roller construction can provide insights into its build quality and whether it justifies its price. A high-quality machine ensures consistent performance and minimizes maintenance costs over time.

Considering Price and Value

Price is closely tied to quality, with higher-quality plate rolling machines typically commanding a premium. However, high prices do not always guarantee superior performance, and low-cost options may lack durability or precision. Comparing quotes from multiple manufacturers is essential to identify the most cost-effective option that meets specific standards and requirements. The goal is to select a machine that offers the best value within budget constraints, balancing quality, performance, and affordability. Avoiding the cheapest models, which may compromise reliability, and the most expensive ones, which may not align with needs, ensures a wise investment.

Evaluating Manufacturer Service

Service quality across pre-sales, sales, and after-sales phases is a critical consideration. During pre-sales and sales, the manufacturer's responsiveness, enthusiasm, and professionalism when addressing inquiries or technical discussions indicate their commitment to customer satisfaction. Reviewing the manufacturer's website, reading online customer feedback, and, if possible, visiting their production facility provide valuable insights into their expertise and service level. After-sales service is equally important, and buyers should inquire about the warranty period, charges for on-site debugging, maintenance processes, operator training, and the availability of local service departments. Checking online reviews and feedback helps gauge the manufacturer's reputation for reliable after-sales support, ensuring long-term operational success.

Practical Tips for Selection

When choosing a plate rolling machine, prioritize suitability over extravagance. Opt for the most cost-effective model that meets specific needs rather than the most expensive or cheapest option. Investing in a brand-new machine from a reputable manufacturer is preferable to purchasing second-hand equipment or unbranded products, which may lack quality assurance. Collaborating with established manufacturers, such as those recognized for their expertise, guarantees better quality, service, and support. This approach minimizes risks and ensures the machine delivers consistent performance tailored to production requirements.

Making an Informed Choice

Selecting the right plate rolling machine requires a thorough understanding of project needs, machine types, and manufacturer reliability. By clearly defining plate parameters and processing requirements, gaining knowledge about hydraulic, mechanical, and roll configurations, and carefully evaluating quality, price, and service, buyers can identify the ideal equipment. Choosing a reputable manufacturer and focusing on cost-effectiveness ensures a machine that delivers precision, efficiency, and durability, enhancing metal fabrication operations for long-term success.

English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español русский

русский Türkçe

Türkçe português

português العربية

العربية Polska

Polska हिंदी

हिंदी Indonesia

Indonesia