Press brake tooling, consisting of punches and dies, is the backbone of sheet metal fabrication, enabling precise bending to create a wide range of components. The punch, the upper tool, applies force to shape the material, while the die, the lower tool, provides support during the bending process. Whether you're working in automotive, aerospace, or custom manufacturing, understanding press brake tooling is essential for achieving high-quality results. This guide dives into the essentials of press brakes, tooling selection, materials, setup techniques, and maintenance practices. By mastering these elements, you can optimize efficiency, ensure precision, and elevate your sheet metal bending operations.

What Is a Press Brake?

A press brake is a powerful machine designed to bend sheet metal into precise shapes by using a vertically moving top beam, known as the punch, and a stationary bottom beam, called the die. The sheet metal is positioned between these beams, and the punch descends to form the desired bend. Available in various types—mechanical, hydraulic, hybrid, CNC, and rotary—press brakes cater to diverse applications, offering unique benefits in precision, power, and automation. From crafting intricate components to producing large structural parts, press brakes are indispensable in modern manufacturing.

Press brakes are widely used in industries like automotive, where they shape parts such as brackets and panels, and aerospace, where precision is critical for structural components. They also play a key role in construction, electronics, and custom fabrication, enabling the creation of everything from enclosures to decorative elements. The versatility of press brakes, combined with the right tooling, makes them a cornerstone of sheet metal processing.

Selecting the Right Press Brake Tooling

Key Factors for Tooling Selection

Choosing the correct press brake tooling is crucial for achieving accurate and efficient bends. The material's properties—type, thickness, strength, and ductility—dictate the appropriate punch and die configurations. For example, thicker or stronger materials like steel require robust tooling, while softer materials like aluminum may need less aggressive setups. The desired bend angle determines the shape of the punch and die, with sharper angles requiring specialized tools. Bend radius is another critical factor, as tighter radii demand precise tooling to avoid material deformation. Tooling configurations, such as V-die openings and punch profiles, must align with project specifications, and the tooling material should be compatible with the press brake's tonnage capacity to prevent damage and ensure optimal performance. By carefully assessing these factors, you can select tooling that maximizes productivity and precision.

Matching Tooling to Project Needs

Different projects require tailored tooling solutions. For high-precision tasks, such as electronics component fabrication, narrow punches and small V-dies ensure fine detail. For heavy-duty applications, like bending thick steel plates for construction, robust standard punches and large V-dies are ideal. Understanding your project's requirements—whether it's a single prototype or high-volume production—helps you choose tooling that delivers consistent results while minimizing setup time and material waste.

Materials Used in Press Brake Tooling

Durable and Resilient Tooling Materials

Press brake tooling is typically made from hardened tool steels or carbide, selected for their outstanding durability, wear resistance, and ability to withstand high temperatures. These materials ensure the tools can handle the rigors of repeated bending, even with challenging materials like stainless steel or titanium. High-quality tooling materials maintain precision over time, reducing the need for frequent replacements and ensuring consistent bend quality across projects.

Benefits of Material Choice

The choice of hardened steel or carbide enhances tool longevity, particularly in demanding environments. These materials resist wear from abrasive metals, maintain sharp edges for clean bends, and tolerate the heat generated during high-tonnage operations. Investing in high-quality tooling materials translates to lower maintenance costs and improved operational efficiency.

Setting Up Press Brake Tooling for Success

Step-by-Step Setup Process

Proper setup of press brake tooling is essential for safe, accurate, and efficient bending. Start by ensuring the press brake bed and tooling are clean to prevent scratches or debris from affecting the bend quality. Align the punch and die precisely to ensure even contact with the material, avoiding uneven or distorted bends. Secure the tooling with the appropriate clamping system to maintain stability during operation. Adjust the press brake's tonnage to match the material's thickness and bend requirements, as incorrect settings can lead to poor results or tool damage. Finally, perform thorough safety checks to verify the setup and minimize risks, ensuring the machine is ready for operation. This meticulous process guarantees consistent, high-quality bends.

Common Setup Mistakes to Avoid

Misalignment of punches and dies is a frequent error that can cause uneven bends or tool damage. Overlooking cleanliness can introduce debris, leading to surface imperfections. Incorrect tonnage settings may result in incomplete bends or excessive wear on tooling. By following a systematic setup routine and double-checking each step, you can avoid these pitfalls and achieve reliable performance.

The Importance of Tool Maintenance

Extending Tool Life Through Maintenance

Regular maintenance is vital for maximizing the lifespan and performance of press brake tooling. Routine cleaning removes debris that could affect bend quality, while lubrication reduces friction and wear. Periodic inspections help identify signs of damage, such as cracks or dull edges, allowing for timely repairs or replacements. Proper maintenance not only extends tool life but also ensures consistent precision, prevents costly downtime, and maintains the quality of your bends.

Maintenance Best Practices

Schedule regular maintenance intervals based on usage intensity. Use appropriate cleaning solutions to avoid damaging tool surfaces, and apply lubricants recommended by the manufacturer. Store tools in a dry, organized environment to prevent corrosion. Training operators on maintenance protocols ensures compliance and enhances overall equipment reliability.

Exploring Press Brake Punches

Understanding Punch Characteristics

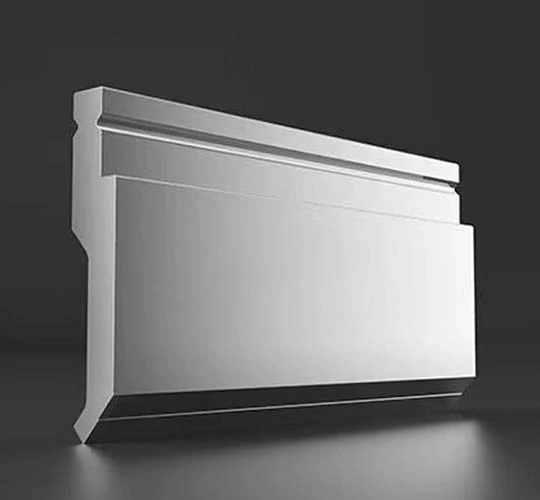

Punches, the upper tools attached to the press brake's ram, shape sheet metal by descending along the bend line, determining the flange height. They are categorized by characteristics like product code, which details mechanical and dimensional properties, and the angle between faces adjacent to the tip radius. Common angles include 90° for coining, 88° for deep drawing, and 30° for needle tools used in air bends or bend-squeeze operations. Punch height influences suitability for deep box bends, while tip radius affects material thickness compatibility, with larger radii ideal for thicker sheets. Load capacity indicates the maximum force a punch can withstand, with swan neck punches offering lower limits due to their design for tight bends.

Types of Punches and Their Applications

Standard punches, with thick bodies and narrow tips, deliver high tonnage for thick materials and allow shorter flange folding. Acute angle punches excel at sharp bends of 30° or less, while narrow punches, or sword punches, fit tight spaces for box profiles. Sash punches are ideal for corner bends, like door jambs, and swan neck punches create U-shaped profiles without workpiece collisions. Joggle punches produce S-shaped bends, and radius top punches create rounded, U-shaped bends when paired with U-dies. Each punch type addresses specific bending challenges, enhancing versatility.

Streamlining with Press Brake Tool Storage

Importance of Efficient Storage

Effective tool storage minimizes downtime and protects press brake tooling from damage. Manual tool handling is time-intensive, but automated tool changers can significantly reduce loading and unloading times. Organized storage systems keep tools accessible, prevent corrosion, and streamline workflows, ensuring tools are ready when needed.

Storage Solutions for Productivity

Dedicated storage racks or cabinets designed for press brake tools maintain organization and protect against environmental damage. Automated changers integrate storage with the press brake, enabling rapid tool swaps. Implementing these solutions enhances operational efficiency, particularly in high-volume or multi-tool environments.

Mastering press brake tooling—from selection and setup to maintenance and storage—unlocks the full potential of your sheet metal fabrication process. By choosing the right punches and dies, using durable materials, and optimizing setup and clamping systems, you can achieve precise bends with minimal waste. Regular maintenance and efficient storage further ensure long-term performance and productivity. Whether you're a small shop or a large manufacturer, this guide empowers you to enhance your press brake operations, delivering high-quality results that meet the demands of today's competitive industries.

English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español русский

русский Türkçe

Türkçe português

português العربية

العربية Polska

Polska हिंदी

हिंदी Indonesia

Indonesia