Waste Tire Replacement Fuel (TDF) System

Used tires have long been used as a supplementary fuel to coal and wood. Over the years, more and more incineration plants have begun to use used tires, not only because of their high energy content, but also because they are cheaper than coal, produce cleaner emissions, and have low moisture content. The high calorific value of used tires makes them an ideal alternative fuel for energy-intensive industries such as cement plants, power plants, pulp mills, and paper mills.

Biomass Content

| Paramete | Used car tire | Used truck tire | Coal | Oil coke |

| Biomass | 17-20.3% (average 18.3%) | 28.6-29.7% (29.1 %) | 0% | 0% |

| Carbon | 67.5-70.1% (average 69.0%) | 59.7-62.6% (61.1%) | 64-68% | 84-97% |

| Net calorific value (NCV) (MJ/kg) | 29.5-30.6 (average 30.2) | 26.1-26.7 (26.4) | 26 | 32 |

(The above figures are taken from the Aliapur study.)

Due to the high biomass content of burning scrap tires and their derivative fuels, they produce less fossil carbon dioxide emissions than coal and petroleum coke. Scrap tires are an excellent alternative fuel. They are cheaper and produce less fossil carbon dioxide emissions, but their heat output is roughly the same as traditional fuels.

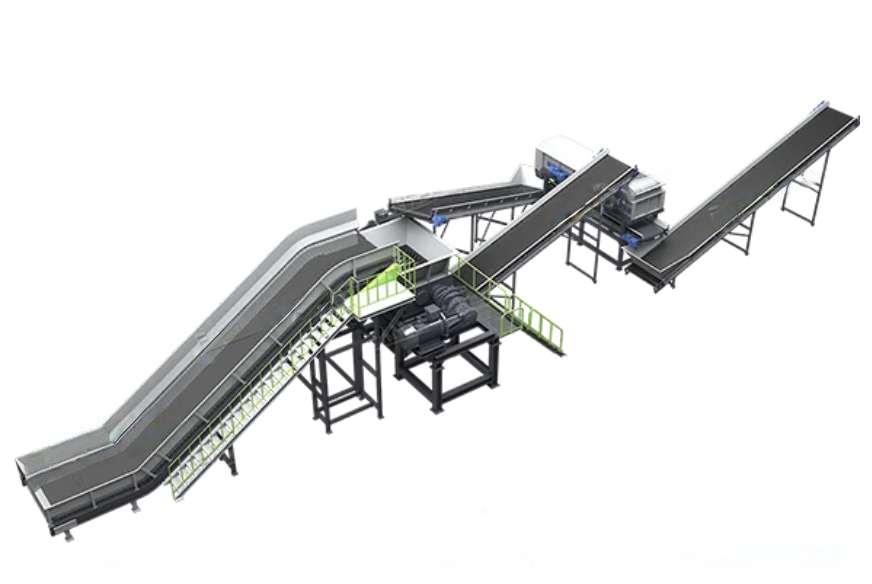

Waste Tire Replacement Fuel (TDF) System Main Equipment

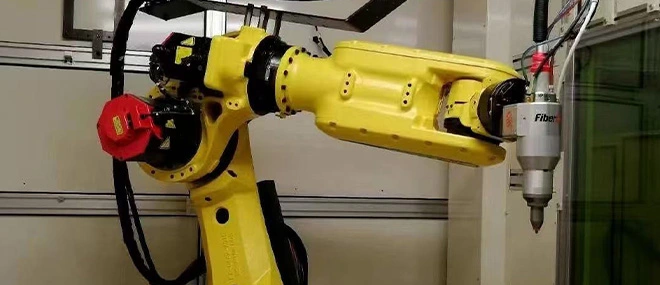

Shredder

The shredder is the ultimate solution for efficient material shredding, suitable for a wide range of applications. Achieve top-tier shredding performance.

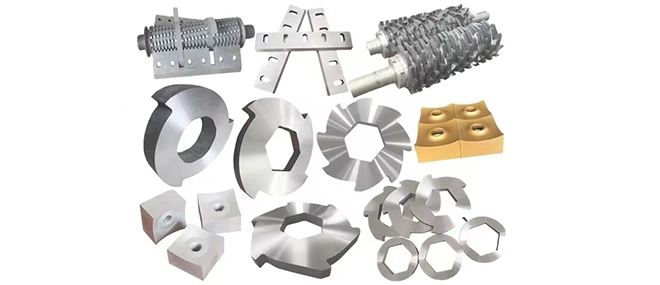

Rasper

The rasper is a critical machine in the tire recycling process, used to process pre-shredded tires into smaller rubber particles.

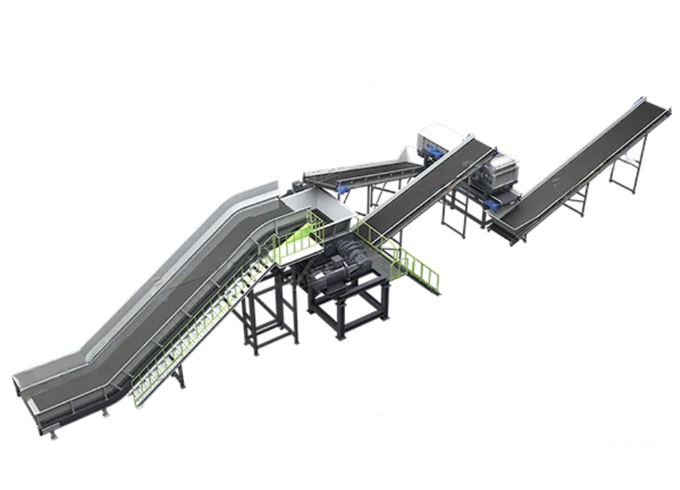

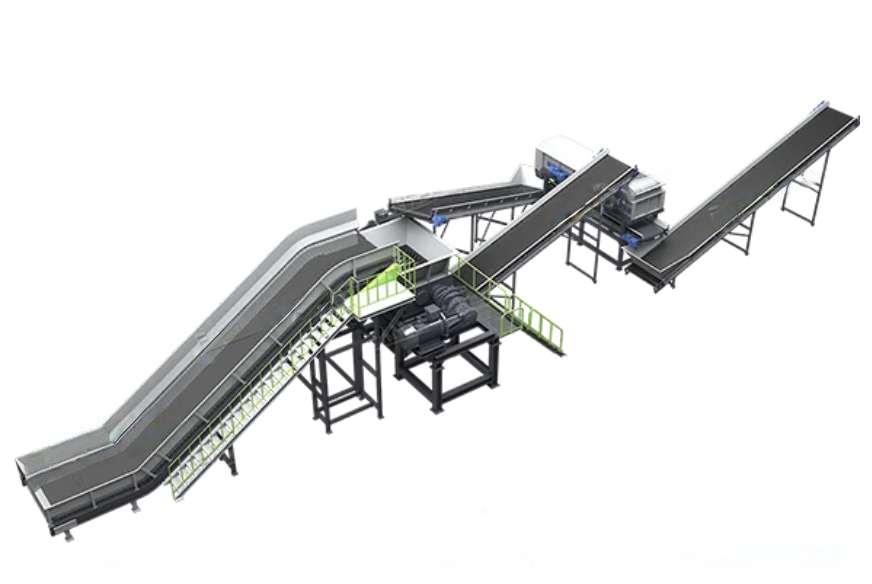

Chain Conveyor

The chain conveyor efficiently transports used tires to the shredder for processing. Designed for heavy-duty applications, it ensures smooth conveying and reduces manual labor.

Disc Screen

The disc screen effectively sorts tire chunks by size, separating oversized pieces to ensure uniformity and simplify the recycling process.

What is tire-derived fuel?

Tire-derived fuel is made by shredding old tires, usually into 1- to 2-inch pieces. The shredding process not only shrinks the tires, but also uses powerful magnets to remove fabric and metal wires. Since TDF requires these processes, it is not as cost-effective as whole tires, but manufacturers still need it because not all combustion equipment can accommodate whole tires.

Some cement plants use whole tires in their kilns because their combustion equipment is large enough, and the metal wires add the iron needed to produce clinker. On the other hand, paper and pulp mills need to use TDF with the metal wires removed to avoid clogging the boiler feedwater system and to prevent iron from being mixed into the ash sold to farmers. TDF comes in several grades, with wireless TDF costing 50% more than regular TDF.

Waste Tire Replacement Fuel (TDF) System in Different Industries

Cement Plants

The cement industry uses more waste tire fuel than any other industry. Cement plants use tires as fuel to produce clinker, which is the main component in the manufacture of Portland cement.

Paper Mills

The pulp and paper industry uses approximately 26 million tires annually as boiler fuel. Pulp and paper mills use TDF rather than whole tires because metal wires can clog the feed

system.

Power Plants

Power plant boilers burn coal to generate electricity. Due to TDF's high calorific value and low cost, power plants currently use TDF as a supplementary fuel to coal.

Industrial Boiler Plants

Industrial boilers are typically smaller than those in power plants and also use TDF as a supplementary component of their fuel mix.

Waste Tire Replacement Fuel (TDF) System Main Process Flow

Tire collection and storage: Collect used tires from various sources, sort them, and store them in designated areas.

Shredding: Use a shredder to tear the tires into pieces, typically around 50 millimeters in size, to meet the requirements of different industrial furnaces.

Slaughtering

Magnetic separation to remove metal: Use magnetic separation equipment to remove metal components such as steel wires from the tires to ensure smooth combustion.

Fuel Preparation and Conveyance: Processed tire fragments are prepared into alternative fuel meeting specifications and conveyed into industrial furnaces for combustion via a conveying system.

Waste Tire Replacement Fuel (TDF) System Advantages

High calorific value: The calorific value of waste tires is higher than that of traditional fuels, providing a higher energy output.

Cost reduction: Using TDF reduces dependence on traditional fossil fuels, thereby lowering fuel costs.

Environmental benefits: By utilizing waste tires as fuel, the accumulation of waste tires and landfill disposal can be reduced, thereby lowering the risk of environmental pollution.

Reduced carbon dioxide emissions: TDF produces lower carbon dioxide emissions during combustion compared to traditional fuels like coal, contributing to reduced greenhouse gas emissions.

English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español русский

русский Türkçe

Türkçe português

português العربية

العربية Polska

Polska हिंदी

हिंदी Indonesia

Indonesia