Waste Tire Recycling Line Solution Background

With the rapid development of the automotive industry, te demand for tires is growing. Tire production line is a key manufacturing process for producing all kinds of tires, ranging from small car tires to large commercial vehicle and construction machinery tires. It consists of multiple processes such as molding, pressing, curing and testing. An efficient and precise production line is the key to ensuring tire quality, increasing production and reducing costs. In this highly competitive market, tire production line technology continues to innovate to meet growing global demand.

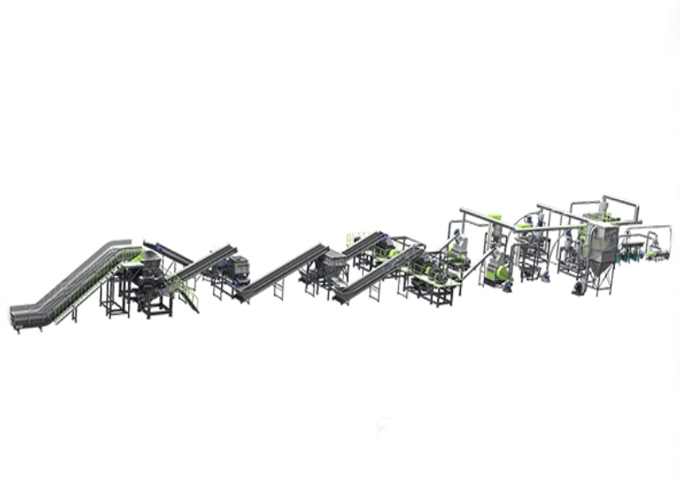

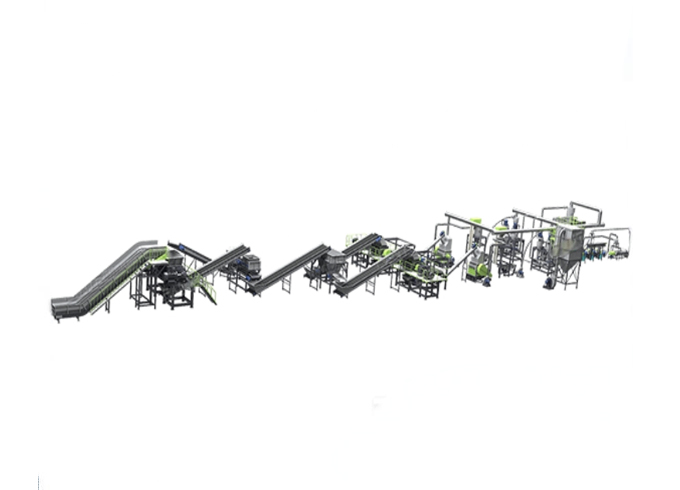

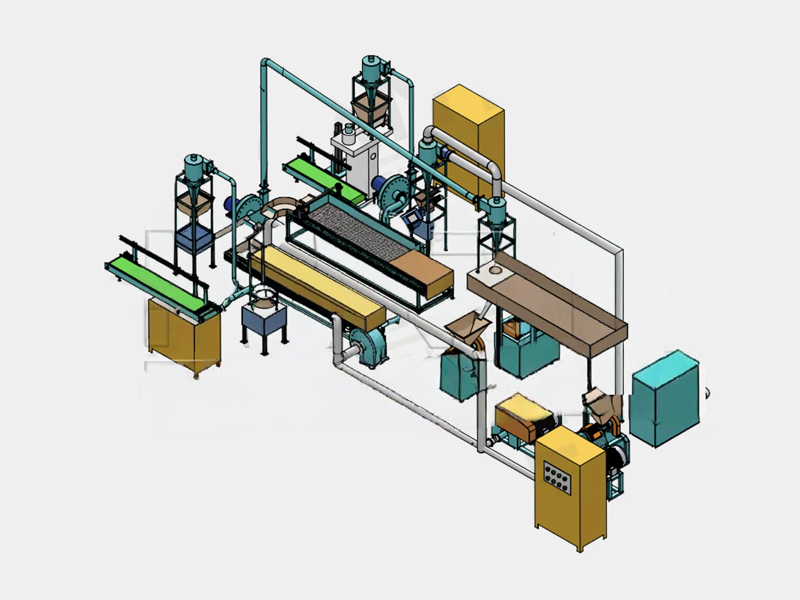

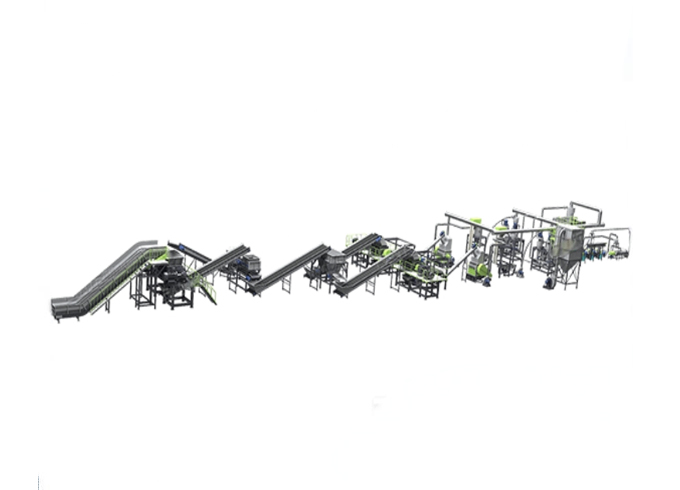

Waste Tire Recycling System Description

The Scrap Tire Recycling System efficiently processes scrap tires into valuable materials such as rubber pellets, steel wire and alternative fuels (TDF). The system's multi-stage crushing, automatic separation and energy-efficient design ensures high throughput, minimal waste and sustainable utilization of resources for a variety of applications.

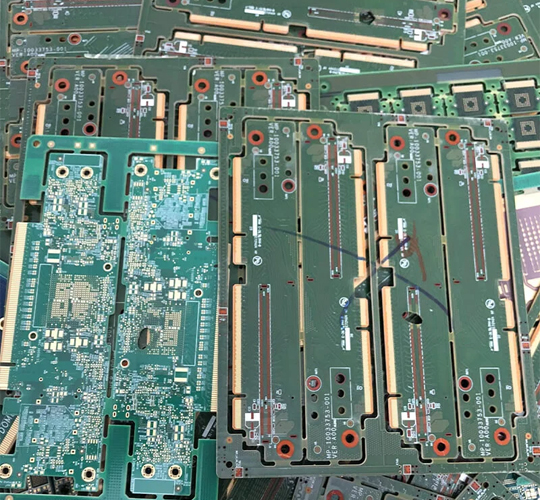

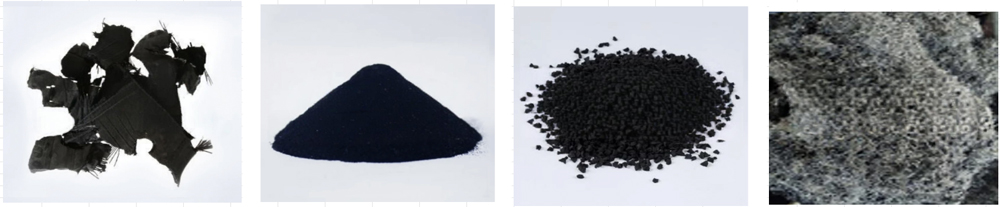

Waste Tire Recycling Line Applicable Materials

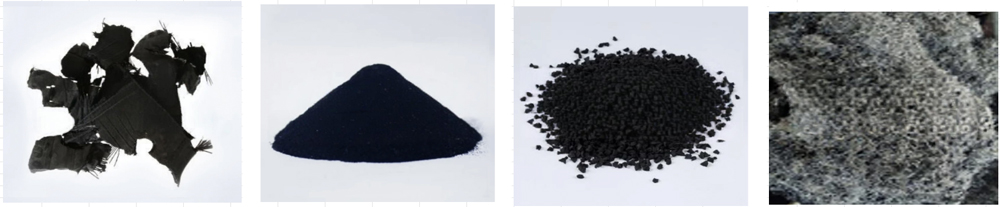

Waste Tire Recycling Line Export Material

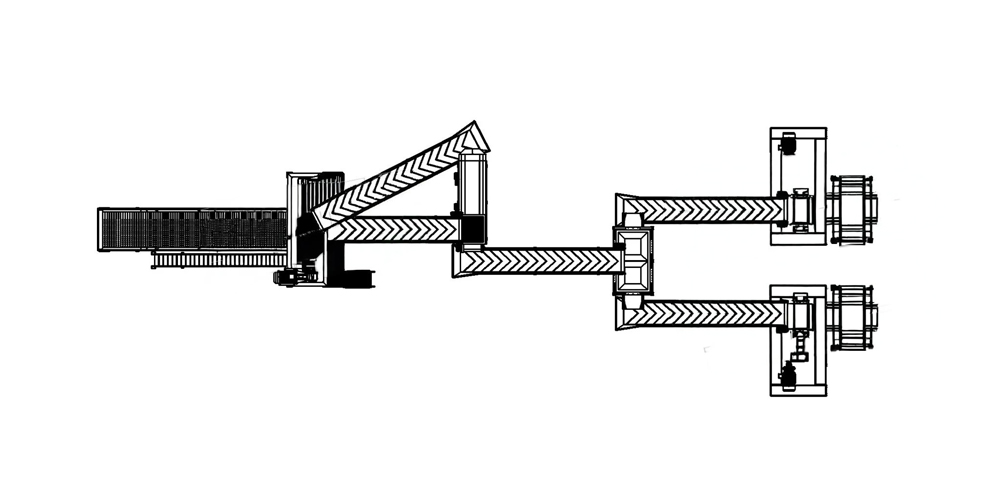

Waste Tire Recycling Line Disposal Solutions

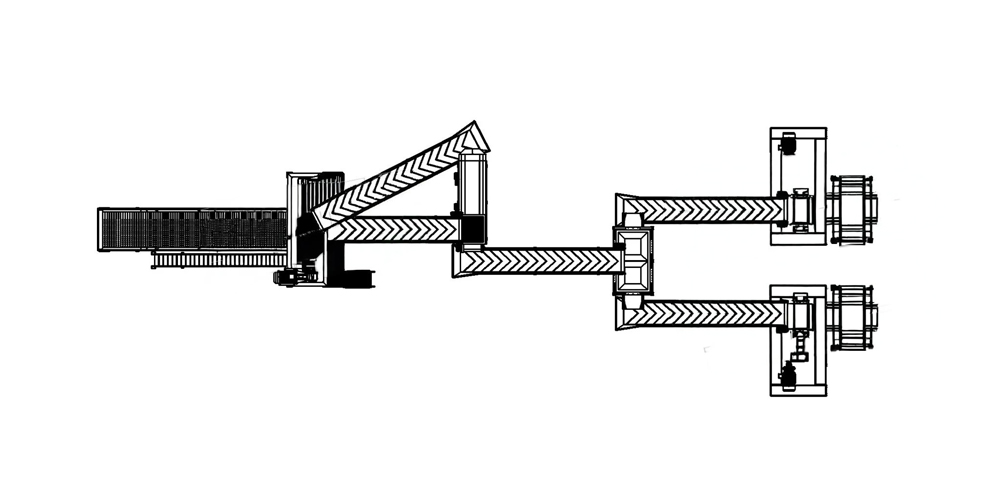

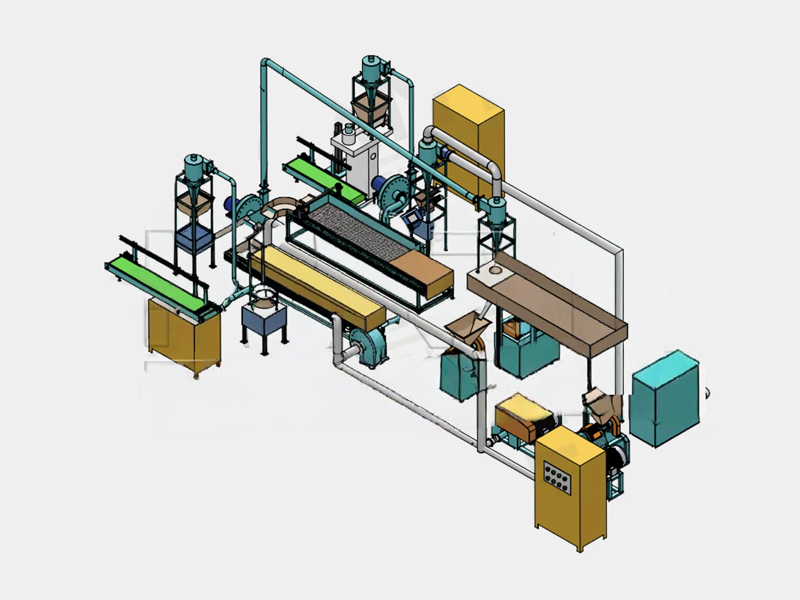

Waste Tire Recycling System Main Equipment

Tire Shredders

Shredders are the ultimate solution for efficient material shredding for a wide range of applications. Get top shredding performance.

Disc Screens

Disc Screens efficiently sort tire chunks by size, separating oversized pieces to ensure uniformity and streamlining the recycling process.

Tire File

Designed for tire recycling, it crushes efficiently, contributing to environmentally friendly processing and resource recovery.

Rubber Crusher

Our advanced solution efficiently crushes and recycles materials. Tailored for a variety of applications, this solution optimizes waste processing.

Waste Tire Recycling Line Performance Advantages

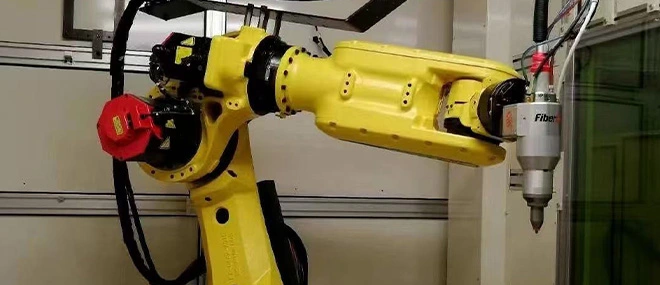

Advantages of Tire Shredder

The Tire Shredder is a multi-functional machine designed to process end-of-life tires into smaller, more manageable pieces for recycling or further processing. The shredder uses advanced cutting and shredding technology to efficiently break down whole tires (including rubber, steel wire and fibers) into uniform rubber chips or chunks. The machine plays a vital role in tire recycling lines, efficiently reducing the generation of scrap tires for subsequent processes such as steel wire separation, granulation and production of fine rubber powder. The shredded rubber material can be used for a variety of applications, including rubber mulch, sports field surfaces and rubberized asphalt.

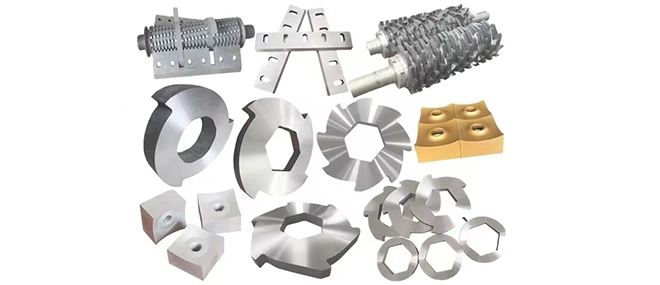

Advantages of Rubber Crusher

Rubber Crusher is a special equipment for processing waste tires into fine rubber particles or powder for recycling. The equipment adopts high-speed crushing technology to efficiently crush rubber chips into uniform particles. Rubber crusher is widely used in tire recycling production lines to produce high quality rubber powder for manufacturing rubber mats, sports grounds, rubber modified asphalt and other value-added products. The machine is designed to be precise, efficient and durable, ensuring stable performance even under continuous operation.

Advantages of Tire File

A rubber crusher (Rasper) is an essential piece of equipment in a scrap tire recycling line, designed to process crushed tire material into smaller, more uniform particles. With its powerful grinding and cutting mechanisms, the Rasper effectively separates rubber from steel and fiber components, preparing it for further refining. This versatile piece of equipment efficiently crushes tires, making it an indispensable part of the recycling process that transforms scrap tires into valuable resources such as rubber granules and steel wire. Its durability and adaptability allow it to meet the demanding requirements of tire recycling, contributing to sustainable waste management solutions.

Advantages of The Miller

Mill is an essential piece of equipment in the tire recycling process, designed to grind rubber particles into ultra-fine rubber powder for high-value applications. The equipment uses precision grinding technology to efficiently process pre-crushed rubber materials to a uniform particle size, typically 30 to 100 mesh. As a key component of a tire recycling production line, the tire mill converts waste tires into fine rubber powder, supporting waste reduction, resource recovery and sustainable production. Its efficient operation contributes to environmental protection and circular economy development.

English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español русский

русский Türkçe

Türkçe português

português العربية

العربية Polska

Polska हिंदी

हिंदी Indonesia

Indonesia