Solution Background:

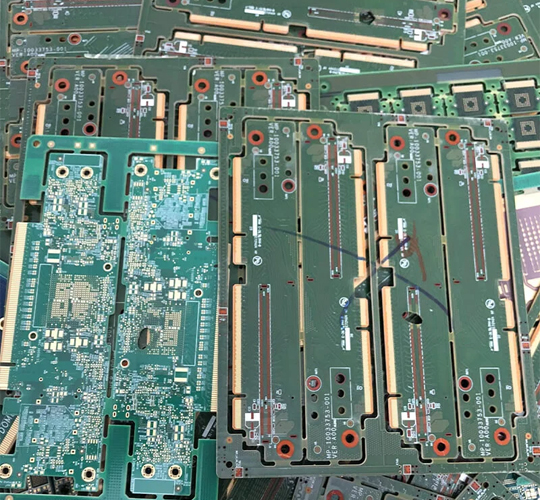

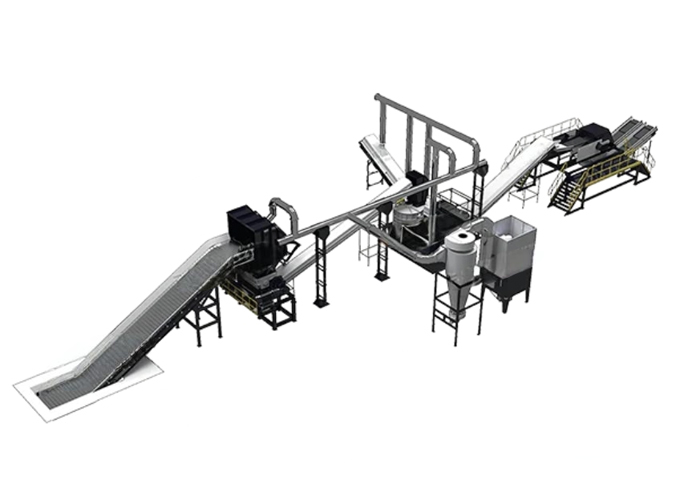

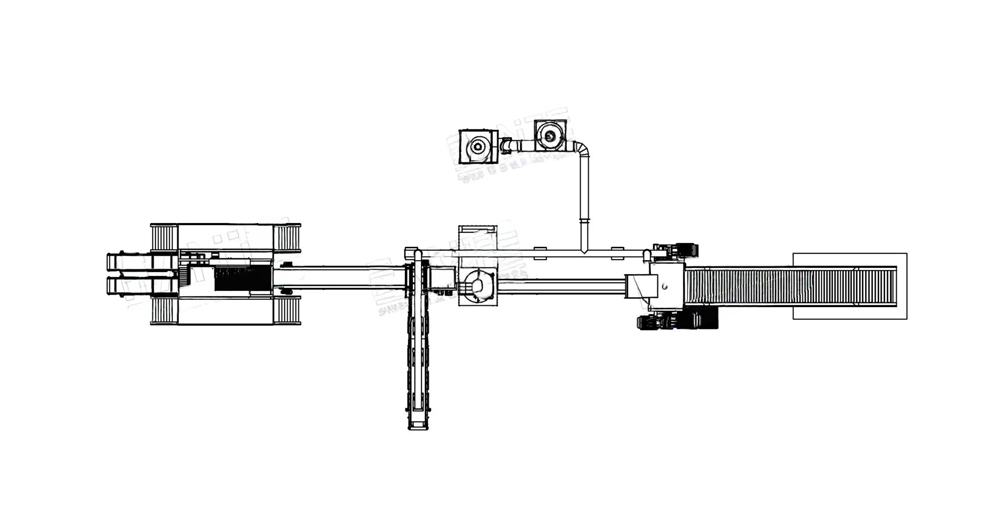

The waste refrigerator recycling system is an environmentally friendly facility specifically designed to process and recycle waste refrigerators. The system uses a series of technologies and processes to classify and utilize harmful substances, safety gases, recyclable materials, etc. in waste refrigerators.

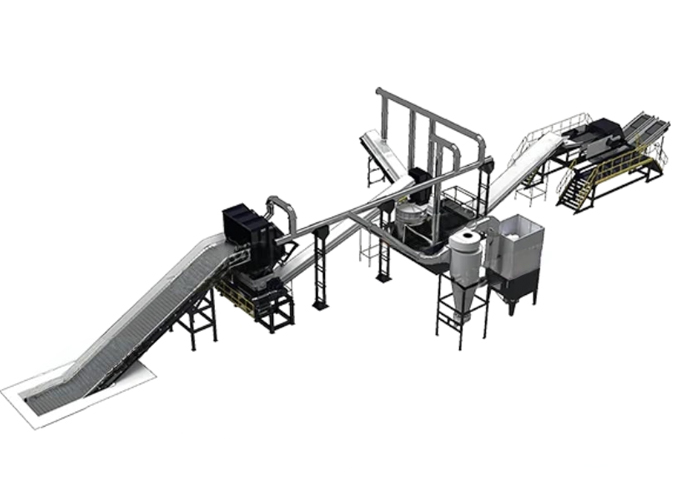

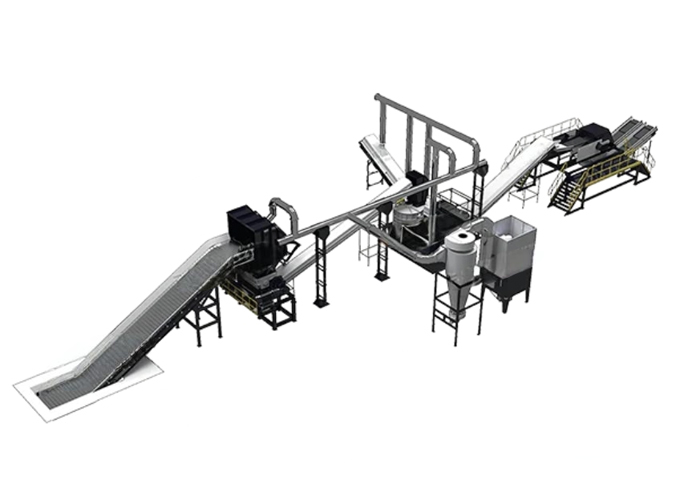

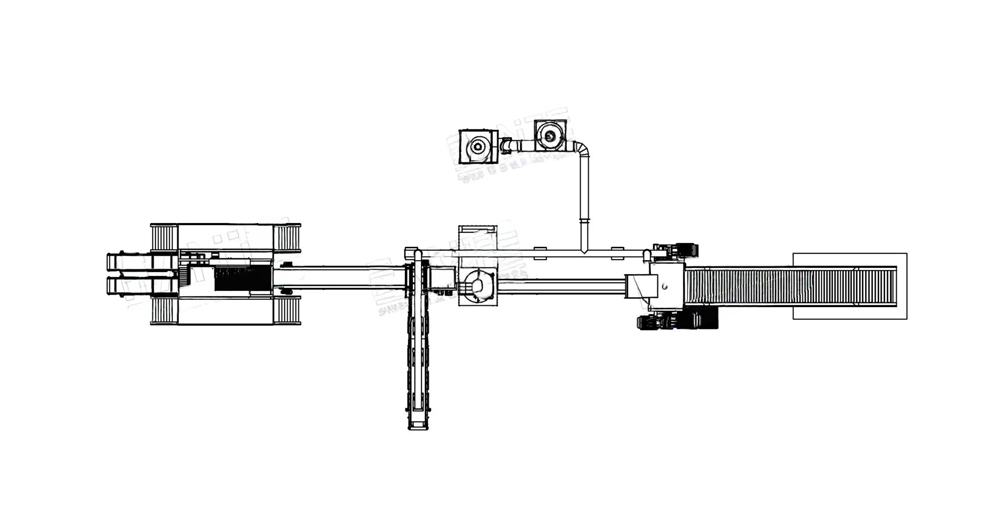

System Introduction

The waste refrigerator recycling system is a system designed specifically for waste refrigerators. It uses advanced technology and processes to effectively dismantle, sort, and process waste refrigerators, maximizing the recovery of useful materials and safely disposing of harmful substances to achieve resource reuse and recycling. The goal of this system is to reduce the negative impact of waste refrigerators on the environment and promote the sustainable use of waste resources.

Applicable Materials:

Output Material:

Disposal Solutions:

Main Equipment:

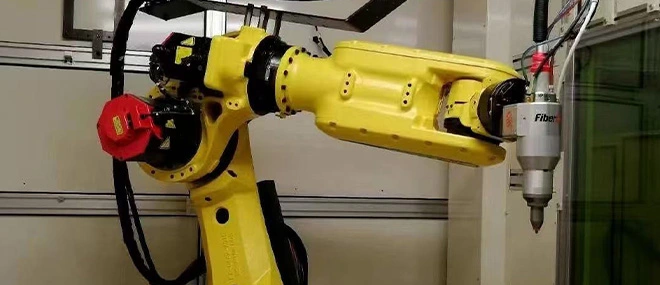

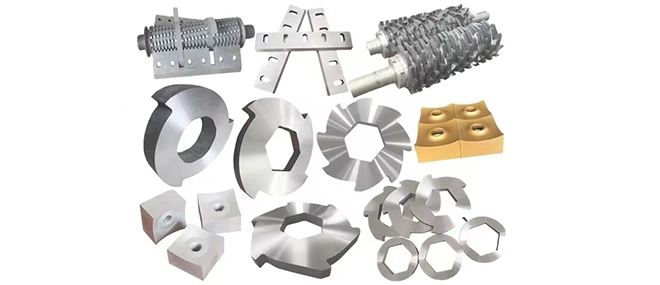

Shredder

Shredders use sharp blades to cut materials into smaller pieces, thereby improving recycling and waste management efficiency.

Vertical Hammer Crusher

Effectively crushes and compresses scrap metal, making it easier to recycle and reducing the storage space required.

Eddy Current Separator

Accurately separates non-ferrous metals from waste streams, improving recycling efficiency.

Pulse Dust Collector

Protects your workplace from airborne particulates, keeping the air clean and healthy.

Performance Advantages:

Shredder

Shredders are typically used to process various materials, including plastic, rubber, scrap metal, and fabric, by cutting, tearing, or crushing them into shapes suitable for subsequent reprocessing or waste disposal. Shredders come in various types, such as metal shredders, plastic shredders, and fabric shredders. Each type has a unique design and functionality, which can be customized according to the characteristics of different materials and processing requirements, thereby achieving efficient processing to meet the needs of various industries. These shredders are efficient, precise, and versatile, playing a crucial role in waste processing and recycling. They are essential in fields such as waste recycling, manufacturing, and resource reuse, providing important processing capabilities for the reuse of various materials.

Eddy Current Separator

An eddy current separator is an efficient metal separation and recycling device. It utilizes the eddy current principle, generating an eddy current effect through a strong magnetic field to separate non-ferrous metals from mixtures. This equipment is commonly used in waste processing, waste recycling, metal recovery, and resource reuse.

Eddy current separators can effectively identify and separate various metals, such as aluminum, copper, and brass, extracting non-ferrous metals from scrap or recycled materials to enhance metal recovery efficiency. Its operating principle involves utilizing the eddy currents generated by a rapidly rotating magnetic field to create differences in the movement of metallic substances, thereby distinguishing between non-ferrous and ferrous metals.

Vertical Hammer Crusher

The vertical hammer crusher is a highly efficient crushing machine specifically designed for processing scrap metal. Its unique vertical structure and powerful hammer design make it highly efficient in the scrap metal processing industry. The machine employs advanced crushing technology, using high-speed rotating hammers to deliver strong impacts and crush scrap metal, achieving efficient crushing and separation.

The vertical hammer crusher performs exceptionally well in waste metal processing, effectively crushing metal blocks of various shapes and sizes, including scrap automobile parts and scrap steel. Its height-adjustable discharge port design allows it to accommodate metal scrap of different specifications, offering flexible production configuration options.

English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español русский

русский Türkçe

Türkçe português

português العربية

العربية Polska

Polska हिंदी

हिंदी Indonesia

Indonesia