Solution Background:

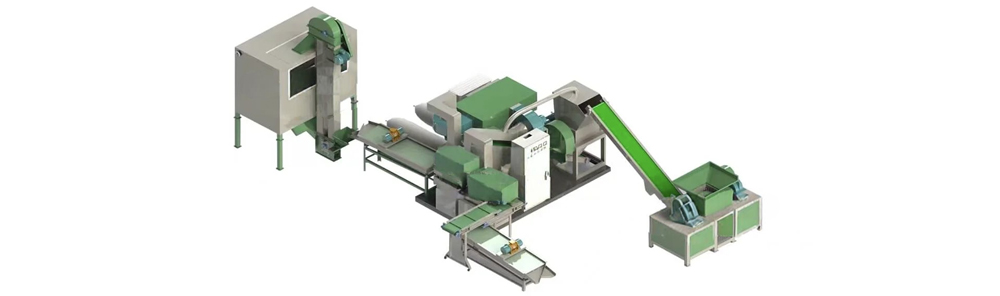

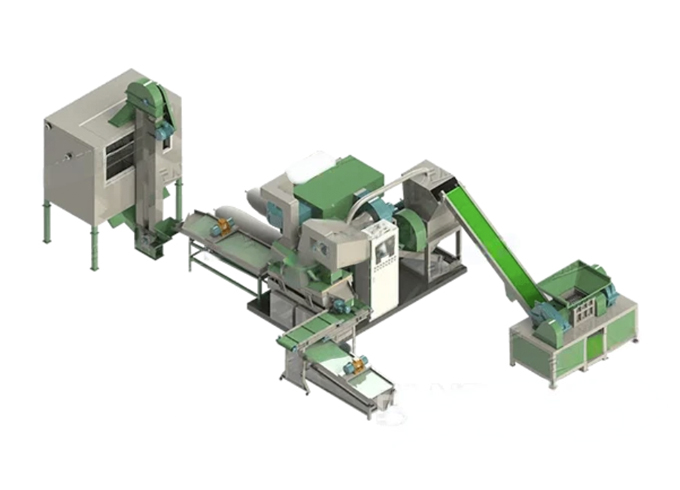

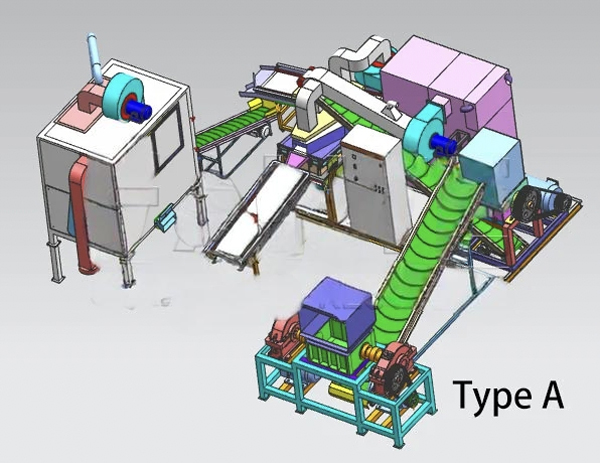

Our waste wire recycling system is an advanced automated production line designed to process and recycle waste wire. The system employs cutting-edge technology, including crushing, magnetic separation, air separation, and electrostatic separation, to effectively separate metals from insulating materials within the waste wire. The multi-stage process extracts valuable metals such as copper and aluminum while separating plastic and rubber insulation layers. This not only ensures environmentally friendly recycling but also reduces waste disposal costs. The system is an ideal choice for companies specializing in the processing of scrap cables and the recycling of renewable resources, helping to reduce environmental pollution and support sustainable resource utilization.

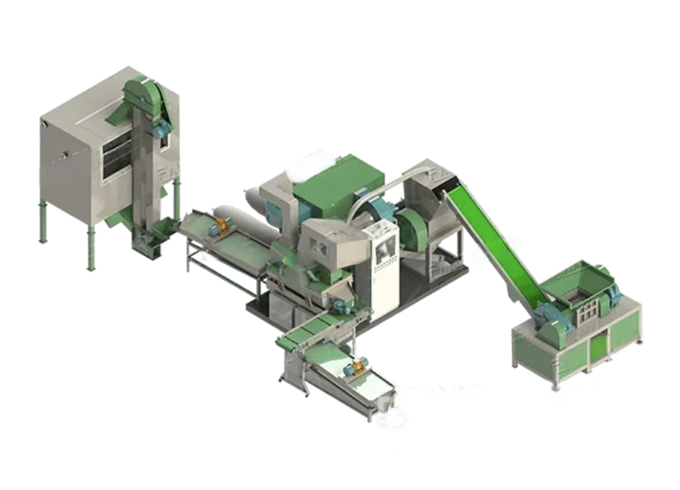

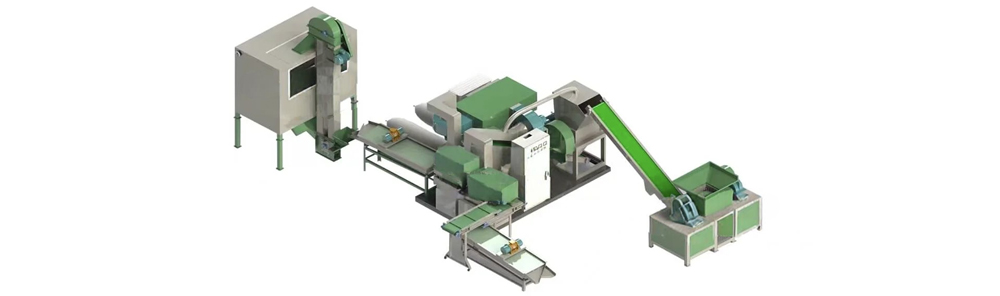

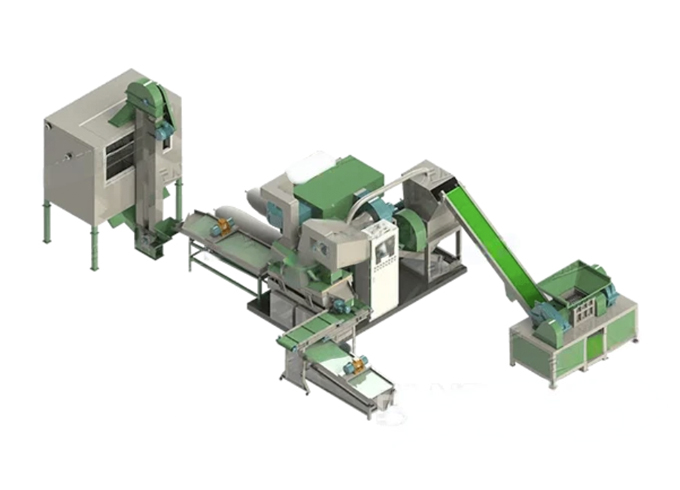

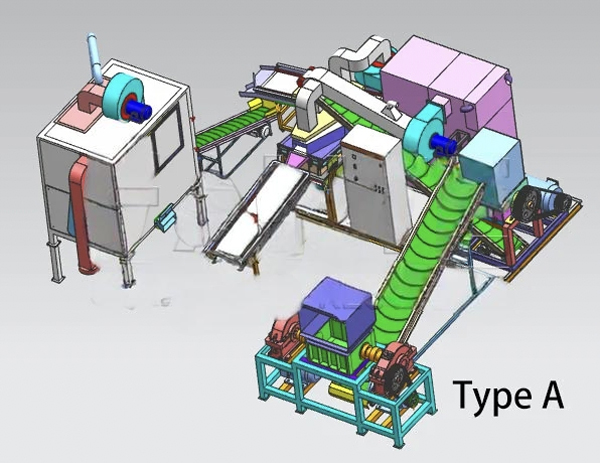

System Introduction

The waste wire recycling system is an innovative treatment solution designed to efficiently recycle and reuse valuable materials from waste wire. The system uses automated equipment to shred, separate, and refine waste wire, accurately extracting metals such as copper and aluminum, and separating insulating materials such as plastic and rubber. The system is easy to operate, significantly reducing the environmental impact of waste wire and improving resource utilization. It is widely used in the cable processing and resource recycling industries, promoting both environmental protection and economic benefits.

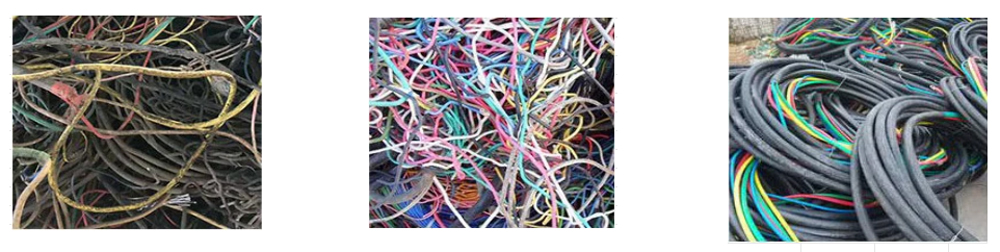

Applicable Materials:

Output Material:

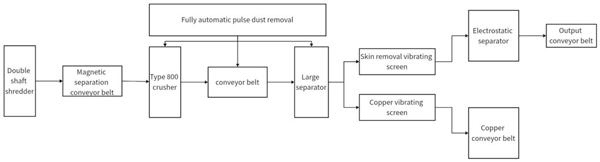

Disposal Solutions:

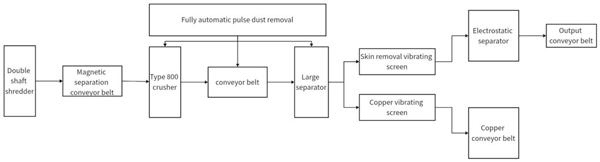

Main Equipment:

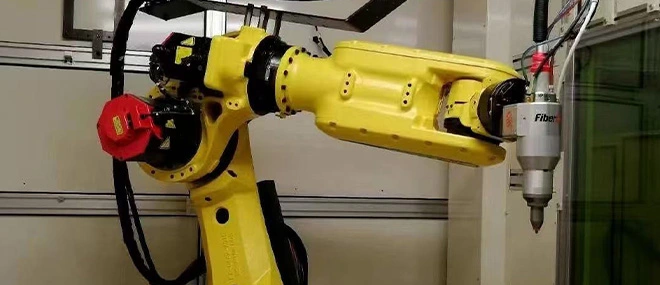

Shredder

A shredder is a mechanical device that tears materials into small pieces or fine fragments, widely used in waste management, recycling, plastic processing, and manufacturing industries.

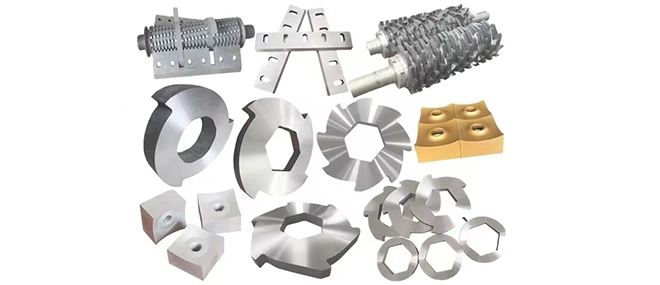

Crusher

A crusher uses high-speed rotating blades or hammers to impact, shear, and grind materials, thereby achieving a crushing effect.

Airflow Separation

An airflow separator is a highly efficient material separation device that uses airflow dynamics to separate materials of different densities and particle sizes.

Dust Collector

A dust collector is a device specifically designed to capture and filter dust and particulate matter generated during industrial production processes.

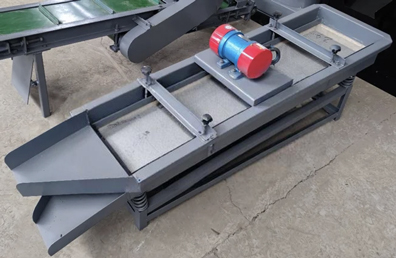

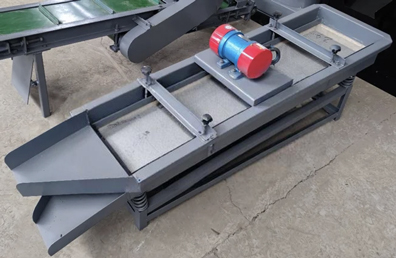

Shaking Screen

A shaking screen is a mechanical device used for grading and screening materials. It utilizes mechanical vibration to cause the screen surface to vibrate, thereby separating materials of different particle sizes.

Vibrating Screen

A vibrating screen is a high-efficiency screening device that uses an electric motor to drive a vibration source, causing the screen mesh to vibrate at a high frequency, thereby screening and grading materials.

Performance Advantages:

Pulse Jet Dust Collector

The dust collector employs multiple technologies to capture and filter dust and particulate matter from the air, thereby improving air quality.

Air Inlet: Dust-laden air is drawn into the dust collector.

Preliminary Separation: Larger particles are separated from the air using methods such as cyclone separation or gravitational settling.

Filtration: Air passes through filtration media such as filter cartridges, filter bags, or filter cylinders, where fine particles are captured on the surface or within the filtration media.

Filter cleaning: The filter surface is regularly cleaned through reverse blowing, vibration, or pulse jet cleaning to maintain filtration efficiency.

Clean air discharge: The filtered clean air is discharged, completing the entire dust collection process.

Electrostatic separator

An electrostatic separator is a highly efficient sorting device that primarily utilizes the charge differences between materials for sorting. The device works by charging the different components in a mixture and then placing them in a strong electric field. Under the influence of the electric field, materials with different charge properties are attracted to different directions, thereby achieving separation. In the recycling industry, electrostatic separators can be used to separate valuable metals and non-metals from electronic waste or to separate different types of plastics in plastic recycling.

Density Separator

A density separator is a device that separates materials based on their density differences. Its working principle involves using airflow, vibration, and the inclination of a screening bed to cause materials of different densities to stratify on the separation bed. Heavier materials settle to the lower layer, while lighter materials float to the upper layer, and they are discharged through separate outlets.

English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español русский

русский Türkçe

Türkçe português

português العربية

العربية Polska

Polska हिंदी

हिंदी Indonesia

Indonesia