Solution Background:

Printed Circuit Boards (PCBs) play a vital role in modern electronic devices by supporting and connecting electronic components. However, with the rapid advancement of technology and the growth of electronic product consumption, the number of discarded PCBs has increased dramatically. This not only wastes valuable resources, but also causes serious environmental pollution.

Polychlorinated biphenyls (PCBs) contain hazardous substances such as lead, mercury and various rare metals. If not properly disposed of, these substances can leach into soil and water bodies, posing significant risks to the environment and human health. Therefore, it is crucial to enhance the recycling and reuse of PCBs. This will not only mitigate the environmental impact of e-waste, but is also in line with global efforts to promote environmental protection and the sustainable use of resources.

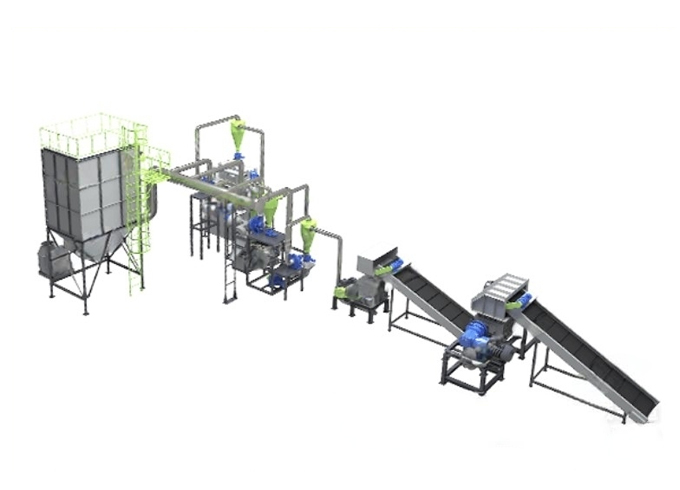

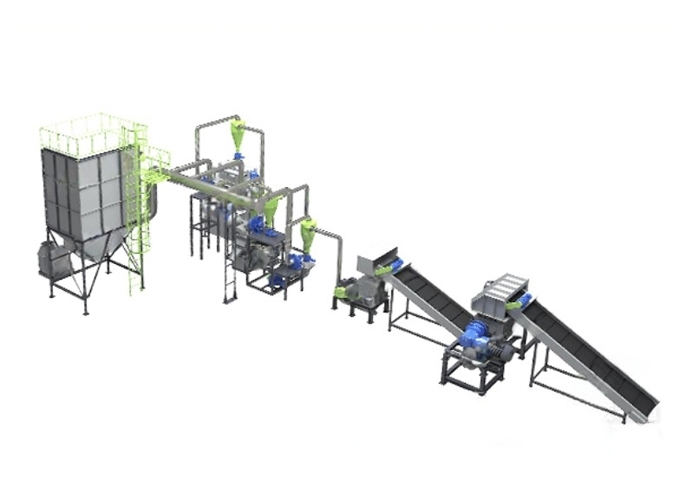

System Description

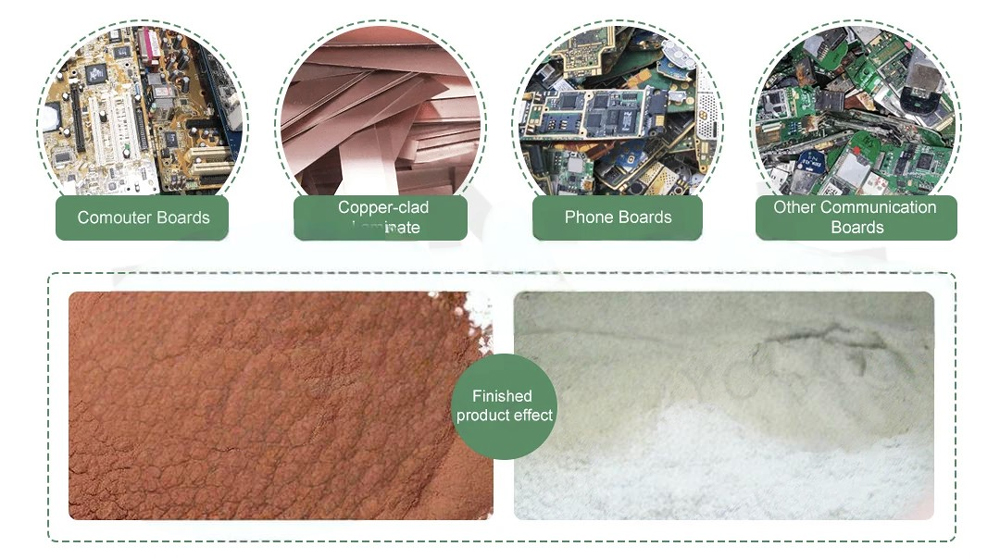

The PCB Recycling Line is a facility designed to efficiently process and recycle used circuit boards. It is designed to recover precious metals such as copper, gold, silver and rare metals while reusing non-metallic materials. This recycling process not only promotes the reuse of resources and minimizes environmental pollution, but is also in line with the principles of sustainable development.

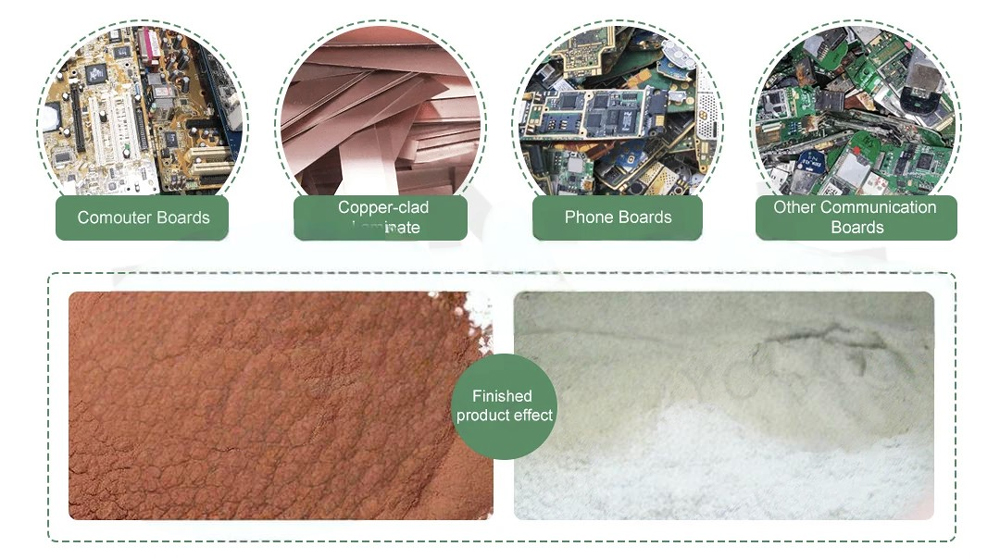

Applicable Materials:

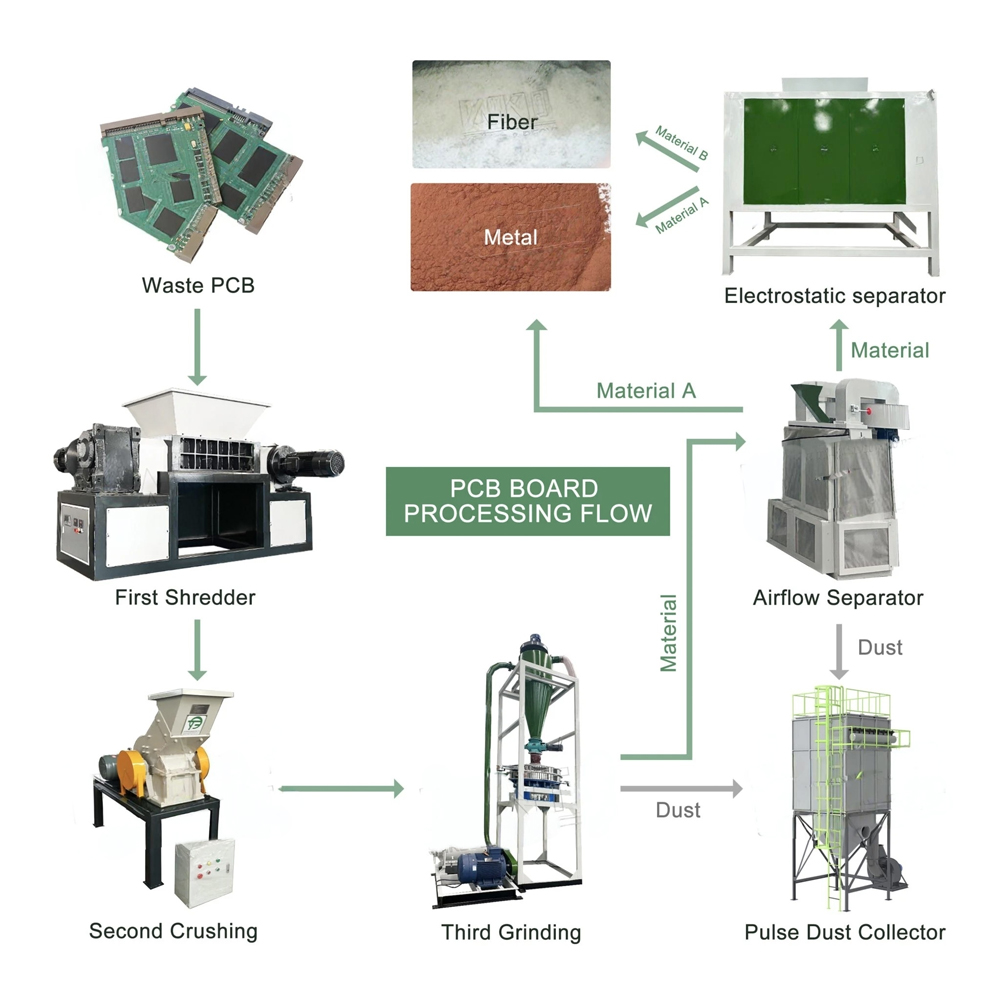

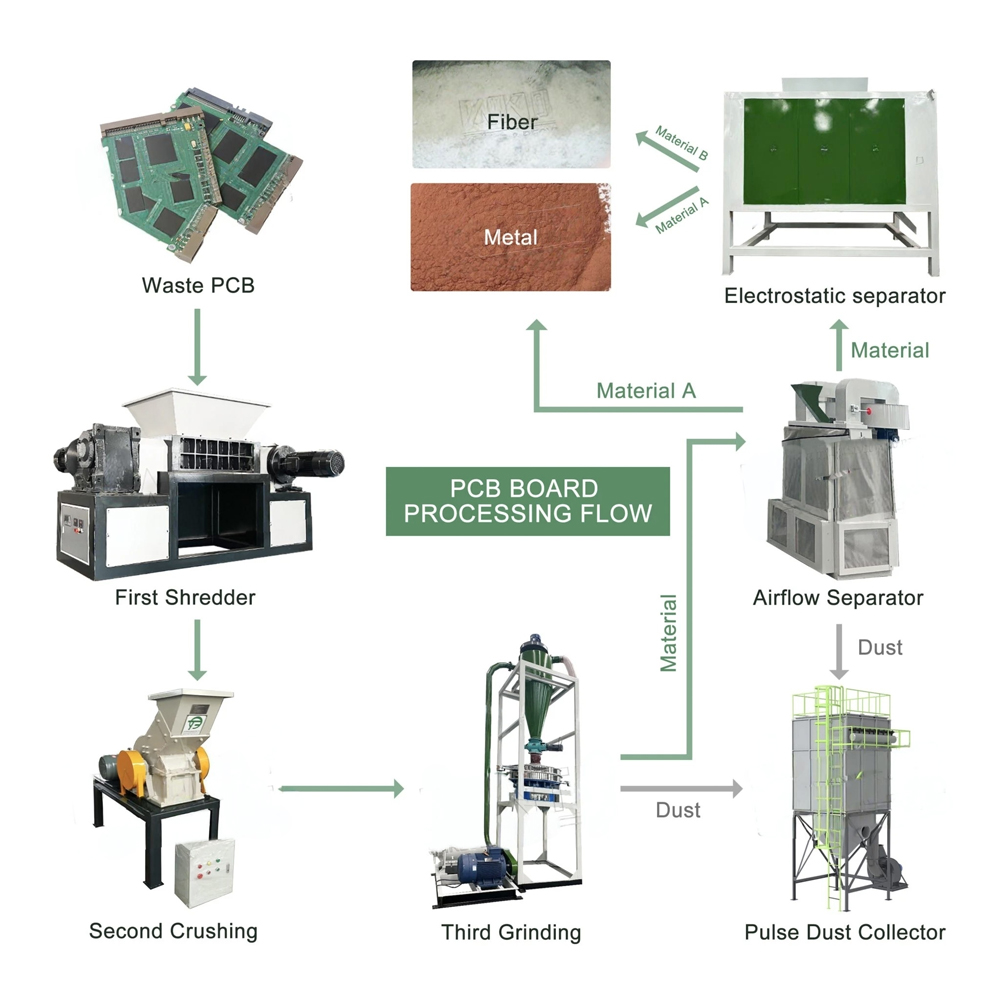

Disposal Solutions:

Main Equipment:

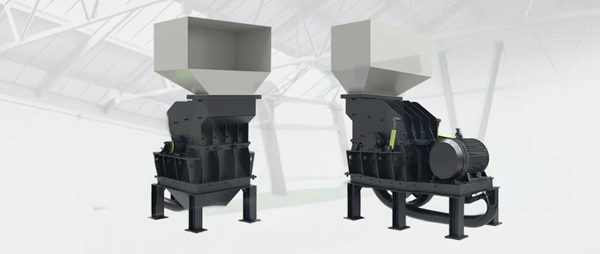

Shredders

Crushers are important pieces of equipment widely used in the recycling and waste management industries to effectively break down various materials into smaller pieces.

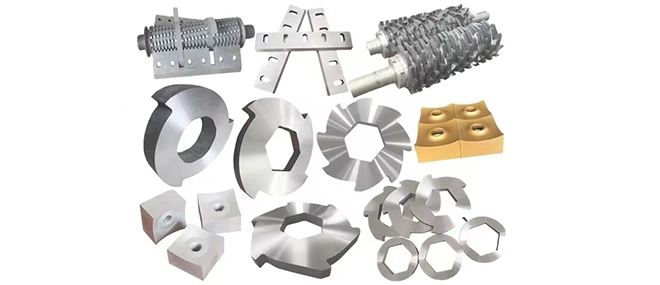

Crushers

Crushers are heavy machinery used in the mining, construction, waste management and many other industries to break down large materials into smaller particles or fragments.

Grinding

Grinding is a widely used material processing technique in industrial production, primarily used to reduce materials to finer or more uniform particle sizes.

Pulse Dust Collector

Pulse Dust Collector is a highly efficient industrial grade dust collector widely used in various manufacturing and processing industries to control the emission of airborne dust and particulate matter.

Air Flow Separators

Air Flow Separators are devices that utilize aerodynamic principles to separate solid particles and are widely used in the recycling, food processing and pharmaceutical industries.

Electrostatic Separator

Electrostatic Separator is a high efficiency sorting equipment specialized in separating mixtures of materials with different conductivity.

Performance Advantages:

Paper Shredder

Shredder is mainly used to cut large materials into small pieces. It is particularly suitable for processing materials such as plastics, paper, wood and metal, and is widely used in the recycling and waste treatment industries. The shredder can be designed as single-axis, double-axis or four-axis. Users can choose the appropriate model according to the cutting requirements and material type.

Crusher

When processing circuit boards, they can be crushed to a fineness of about 20 mesh. This step is usually accomplished using specialized equipment, such as a grinder or crusher. These machines effectively grind the circuit boards into smaller particles, making the subsequent separation and extraction process smoother and more efficient.

Grinding

New grinding disk design with large capacity, good wear resistance and twice the service life of ordinary grinding disks. Circular vibrating screen: large size recovery for secondary grinding. Feedback system makes grinding more efficient. Negative pressure feeding system prevents dust from running out. Air cooler and circulating water system are used to control the temperature and reduce the noise of the grinding system.

English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español русский

русский Türkçe

Türkçe português

português العربية

العربية Polska

Polska हिंदी

हिंदी Indonesia

Indonesia