Details of Bulky Waste Replacement Fuel (RDF) Recycling System

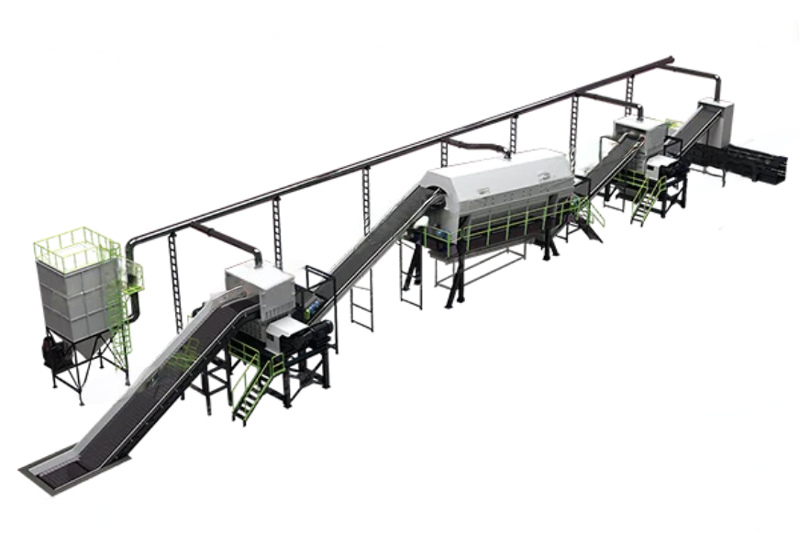

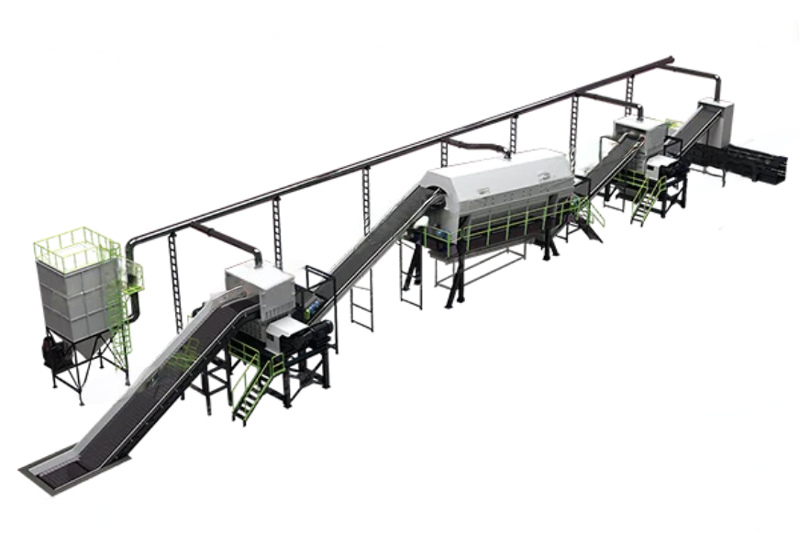

Bulky Waste Replacement Fuel (RDF) Recycling System

As global environmental protection and energy demands continue to grow, alternative fuels (RDF) have emerged as a key solution for efficiently utilizing bulky waste. Our RDF system employs innovative mechanical design to convert bulky waste into high-calorific alternative fuels, providing businesses with environmentally friendly, efficient, and cost-effective solutions.

The RDF system employs a refined processing methodology combining “fully automatic crushing + pulse dust removal + fully automatic air separation + fully automatic magnetic separation + RDF pelletization” to transform these bulky waste materials into “green coal” RDF/SRF alternative fuels. The system can quickly shred and reduce the volume of these bulky waste materials, sort and screen them, and ultimately convert them into “green coal” RDF/SRF alternative fuel. This disposal method is not only efficient but also environmentally friendly, enabling the recycling of resources and effectively processing waste furniture, sofas, mattresses, and other bulky waste materials, turning waste into valuable resources.

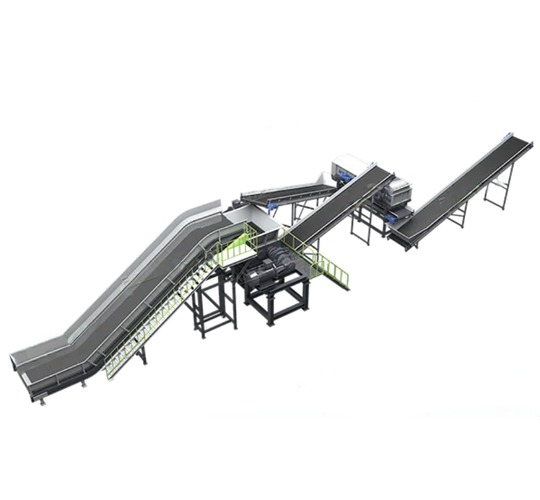

Waste Replacement Fuel (RDF) Recycling System Main Equipment

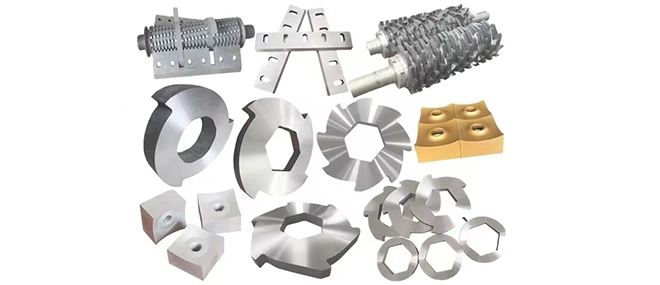

Shredder

The shredder is the ultimate solution for efficient material crushing and is suitable for a wide range of applications. Achieve top-notch shredding performance.

Pulse Dust Collector

The crushing and conveying processes generate dust, which can be controlled using a pulse dust collector. The pulse dust collector collects dust through pipes, improving the environment and protecting staff and equipment.

Air Separator

Air separators utilize gravity and airflow to efficiently separate materials: heavier materials settle at the bottom, while lighter materials are blown to the rear conveyor.

Magnetic Separator

Magnetic separators effectively remove metals for recycling while preventing metals from affecting the performance of downstream equipment.

Why Choose Our RDF System?

Efficient crushing: High bulk waste processing capacity.

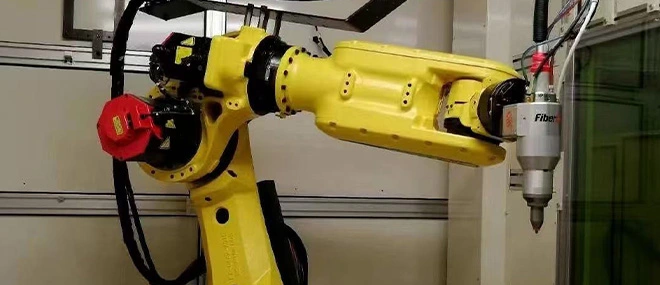

Automated operation: Reduced manual intervention.

Environmentally friendly design: Minimized exhaust emissions.

Flexibility: Customized solutions available to meet customer needs.

Waste Replacement Fuel (RDF) Recycling System Material Disposal

English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español русский

русский Türkçe

Türkçe português

português العربية

العربية Polska

Polska हिंदी

हिंदी Indonesia

Indonesia