CNC Controls of NC Press Brake Machine

The Estun E300P series has the ability to control the X and Y axes and allows the bending steps to be edited directly from the controller.

In addition, the Etune E300P, Delem DA41T and Cybelec CT8 controllers offer additional angle programming capabilities, touch screen displays and R-axis control, all of which help to make the bending process more efficient and user-friendly.

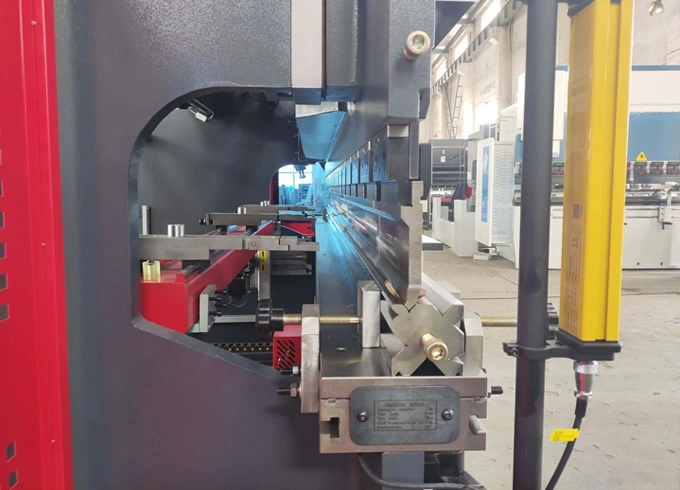

Machine Bed and Machining of NC Press Brake Machine

The accuracy of the bed is ensured by fine machining.

Full annealing of the entire NC press brake machine is essential to minimize distortion and ensure accuracy.

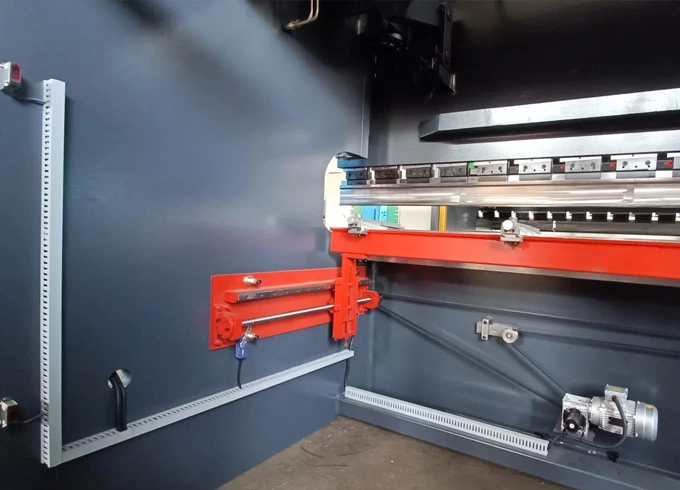

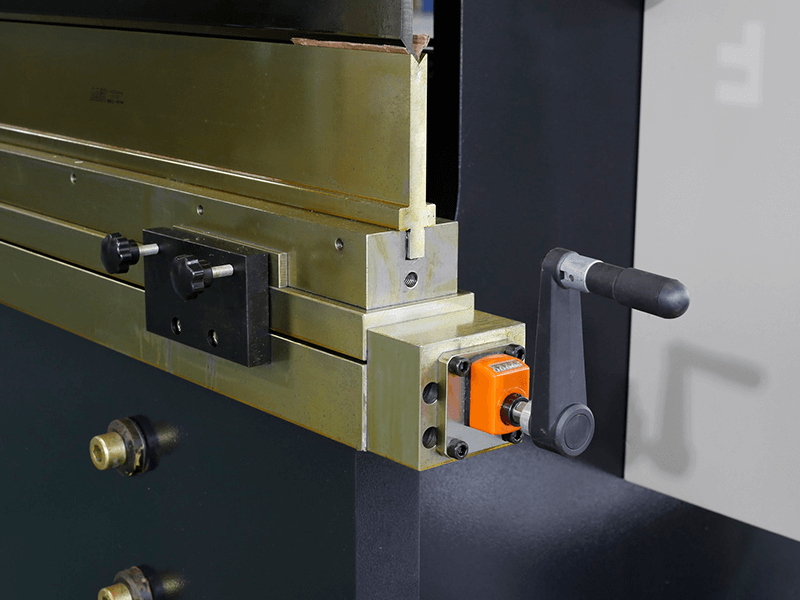

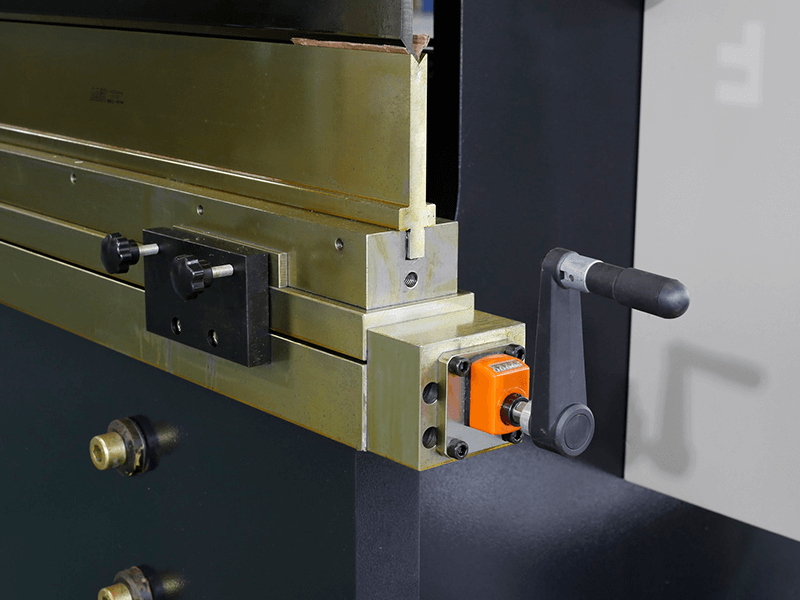

Rear Stop 2-axis XR, Servo-driven of NC Press Brake Machine

The X and R axes of the NC press brake machine are automatically controlled by servo motors.

The R-axis, which may be precisely modified, regulates the movement up and down.

Bending Compensation of NC Press Brake Machine

Mechanically compensated tables are an effective solution to the effects of stamping deflection on bending accuracy for both stamping and pressing brakes. This is achieved by using a multi-point compensation table or a manual deflection compensation table to adjust the bumps at various positions in the center. In addition, it can also correct angular errors at different positions of the workpiece.

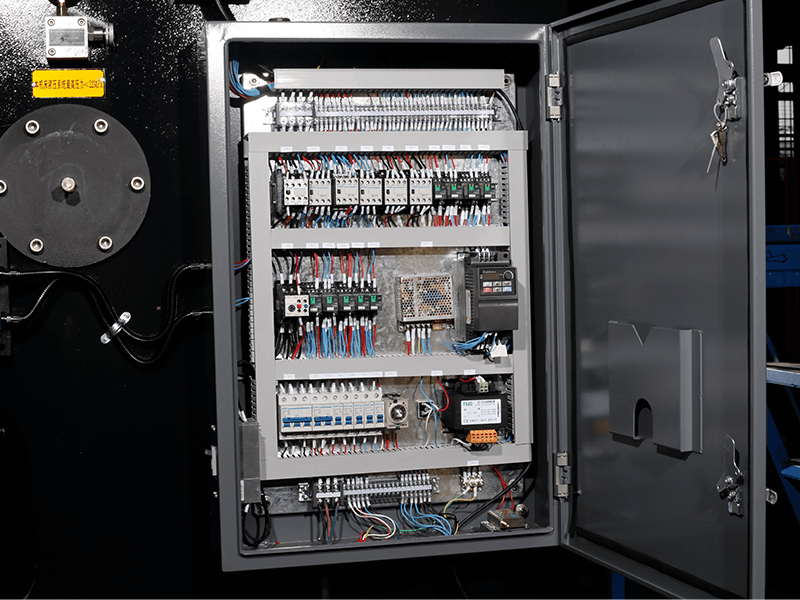

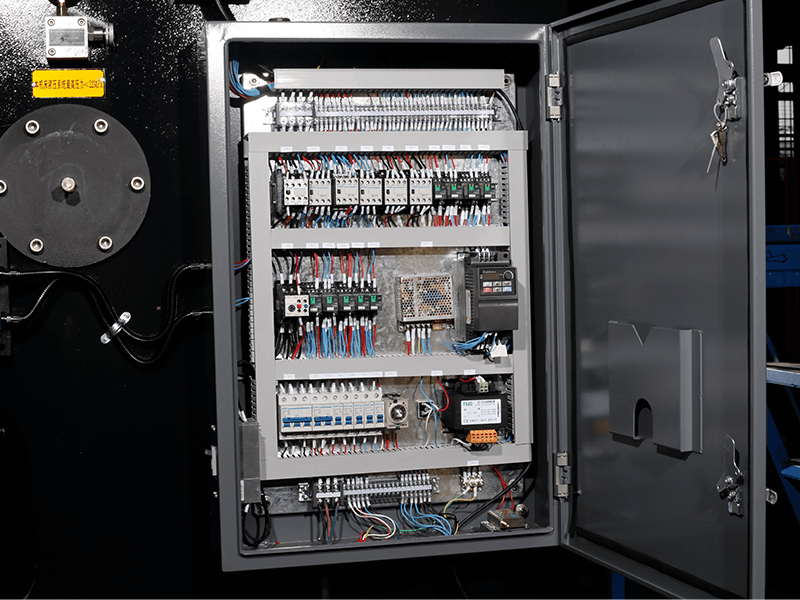

Electrical Parts of NC Press Brake Machine

Since genuine Schneider parts are imported from France, our NC press brake machines operate steadily and long-lastingly, guaranteeing a lengthy service life.

Estun unique adaptive electrical box assemblies, which provide a robust anti-interference capability and guarantee steady electrical operation, are installed in our equipment.

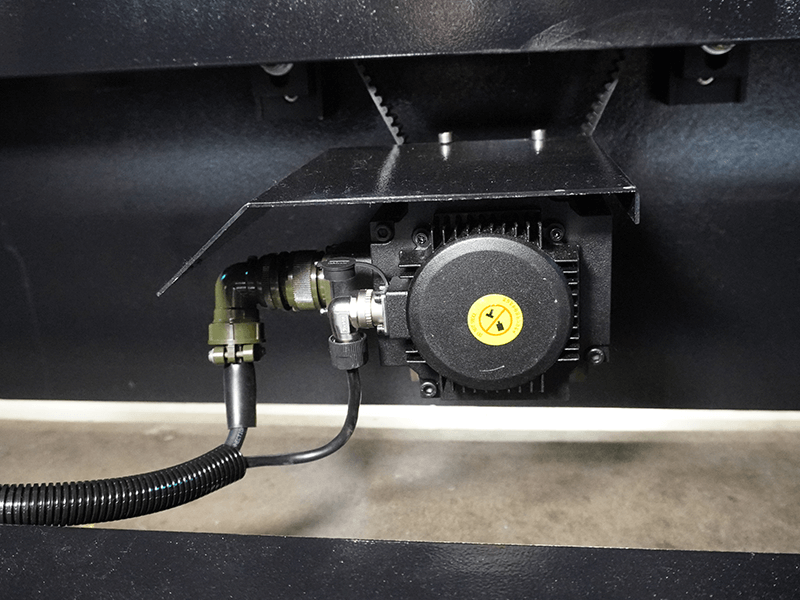

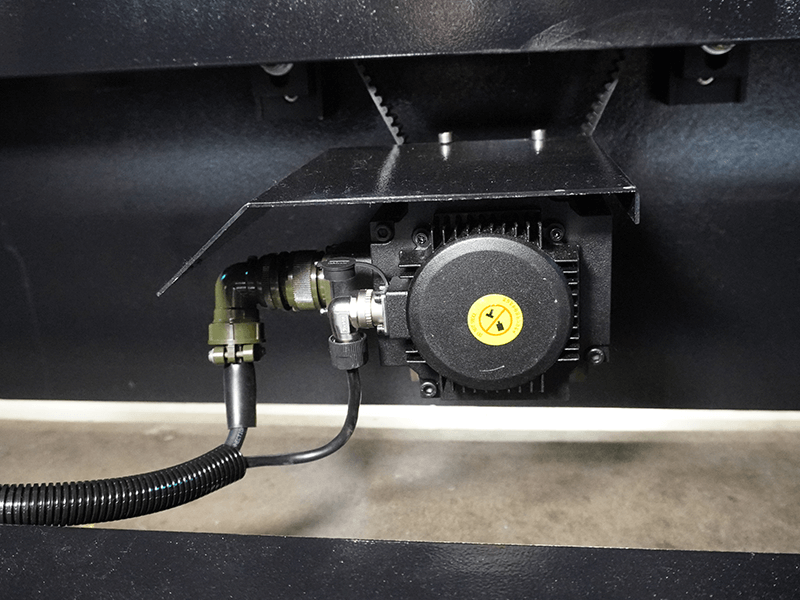

Backgauge Servo Motor of NC Press Brake Machine

The use of a servo motor allows for greater precision control.

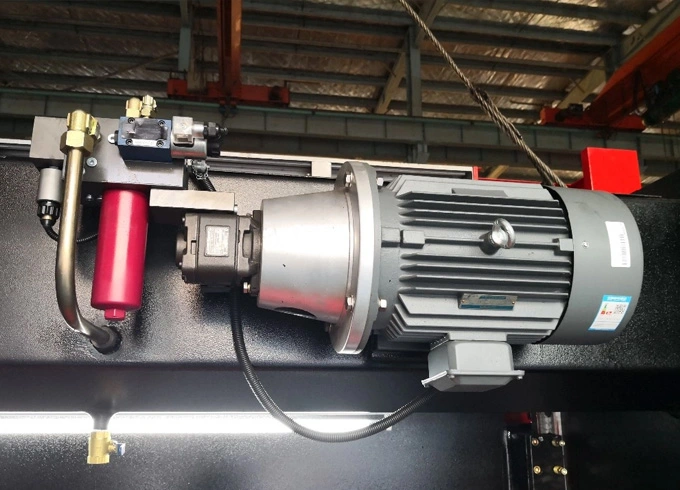

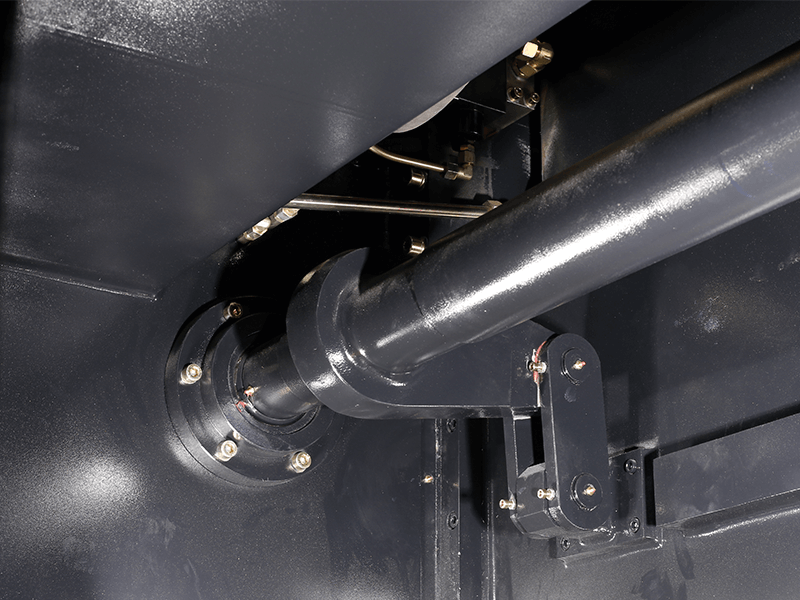

Bosch Rexroth Hydraulic System of NC Press Brake Machine

Cutting-Edge Technology: Bosch Rexroth valves use state-of-the-art technology that ensures excellent performance through precise fluid control.

Robust and Durable: Bosch Rexroth hydraulic valves are renowned for their resilience and are made to endure harsh industrial settings with little upkeep.

Industry-Leading Knowledge: Take advantage of Bosch Rexroth's vast knowledge of hydraulic systems, which produces valves that either match or surpass industry requirements for the best.

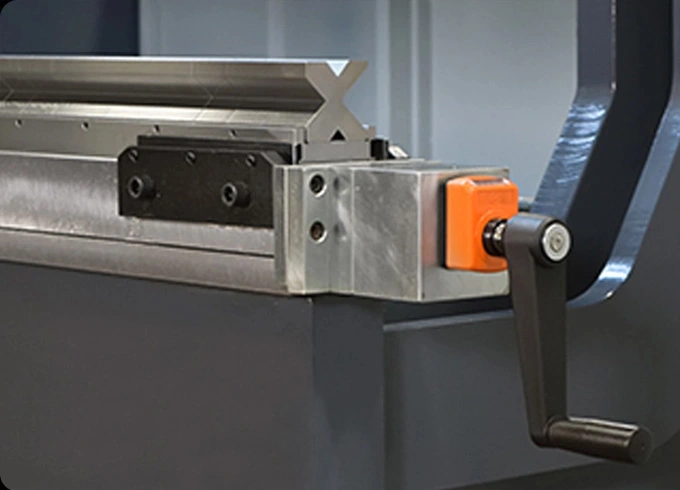

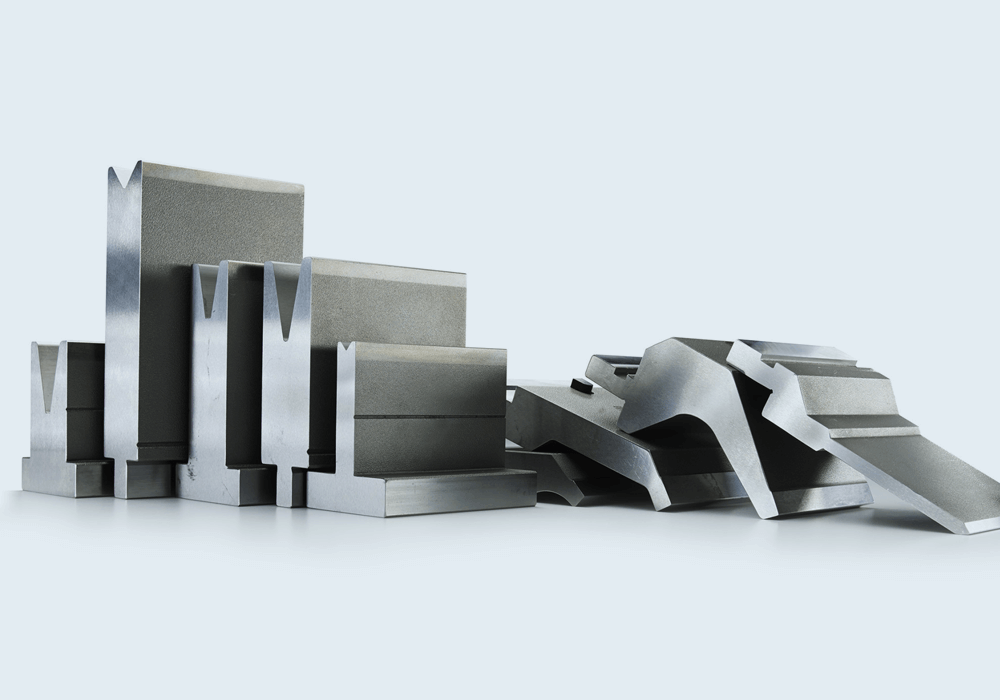

Segmented Punch & Quick Clamp of NC Press Brake Machine

Segmented Upper Die of NC Press Brake Machine:

Precision Bending: Enables precise control for accurate and complex sheet metal bending.

Versatility: Customizable segments accommodate various bending needs, enhancing overall efficiency.

Quick-Change Tooling of NC Press Brake Machine:

Rapid Setup: Swift changeover between different bending applications minimizes downtime.

Increased Productivity: Reduces tooling adjustment time, boosting overall sheet metal bending efficiency.

Siemens Main Motor of NC Press Brake Machine

Reliable Siemens Motors: Our NC hydraulic press brake machine features Siemens main motors, known for their reliability and durability.

Precision Bending: Benefit from the precision and consistent performance of Siemens motors, ensuring accurate control in the bending process.

Advanced Integration: The main motors seamlessly integrate with CNC systems, enabling efficient and precise bending operations.

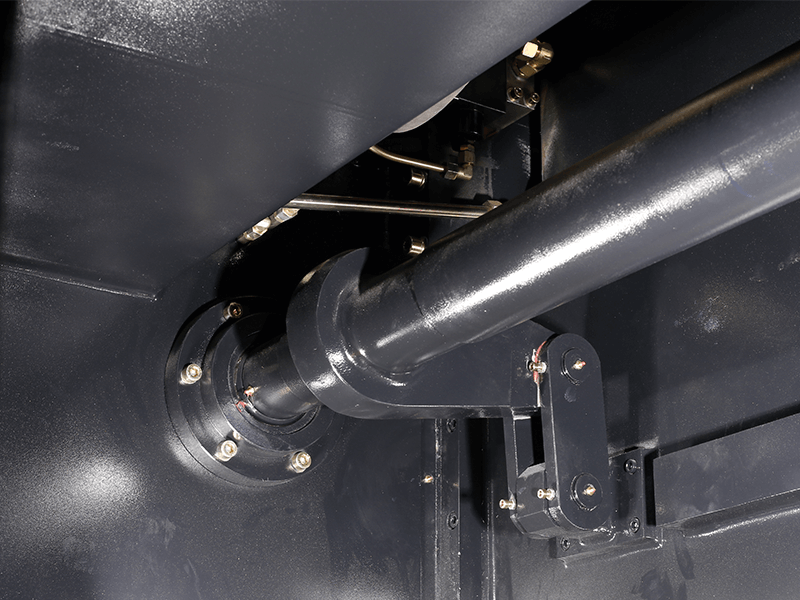

Torsionally Synchronized Levers of NC Press Brake Machine

The torsional synchronization principle controls the vertical movement of the punch.

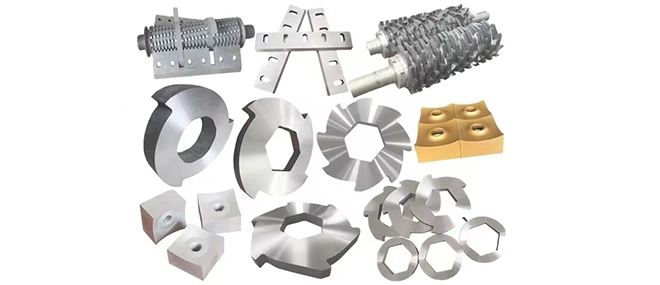

Punches and Dies of NC Press Brake Machine

Before placing an order, it's crucial to talk about NC press brake machine dies and punches. To get the appropriate bending shape, the right punch and die combination is essential. For the particular bending needs of the customer, we can offer the appropriate tooling alternatives.

Processing Equipment of NC Press Brake Machine

Our ability to combine technology and workmanship is demonstrated by our Hydraulic NC & CNC Shears.

Our position as an industry leader is cemented by this state-of-the-art NC press brake machine, which exemplifies our dedication to precise and efficient high-quality metal manufacturing.

English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español русский

русский Türkçe

Türkçe português

português العربية

العربية Polska

Polska हिंदी

हिंदी Indonesia

Indonesia