Details of Heavy Duty Single Shaft Shredder

Heavy Duty Single Shaft Shredder

The single shaft shredder is an efficient waste treatment equipment, designed for the quick and thorough shredding and crushing of various waste materials, plastics, paper, metals, etc. The shredder uses a single powerful rotating blade shaft. Through high-speed rotation and professionally designed blades, waste can be effectively cut into small, controllable pieces, thus achieving waste reduction. Its unique design and innovative working principle make the single shaft shredder machines an ideal choice for the waste treatment and recycling industry. It can not only reduce the amount of waste and improve waste treatment efficiency, but also help companies manage waste more effectively and reduce the impact on the environment.

Product Description of Heavy Duty Single Shaft Shredder

The reducer is a key mechanical transmission device used to reduce the output speed of the drive device (usually an electric motor) and increase the torque by increasing the output torque. This product plays an important role in the industrial and mechanical fields, providing reliable power transmission and control for various applications. The reducer is designed with a precision gear and bearing system to ensure smooth operation and efficient energy transfer. It is widely used in various mechanical equipment, such as conveyor systems, agitators, fans, pumps, etc., to provide these equipment with the required output speed and torque.

.jpg)

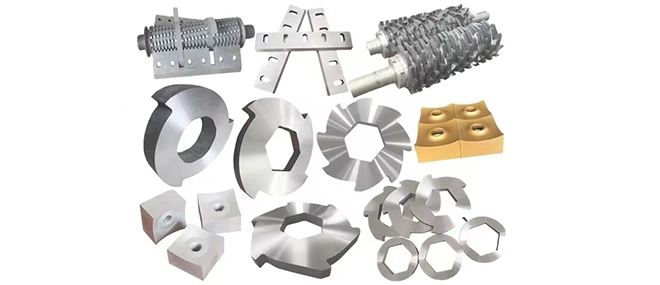

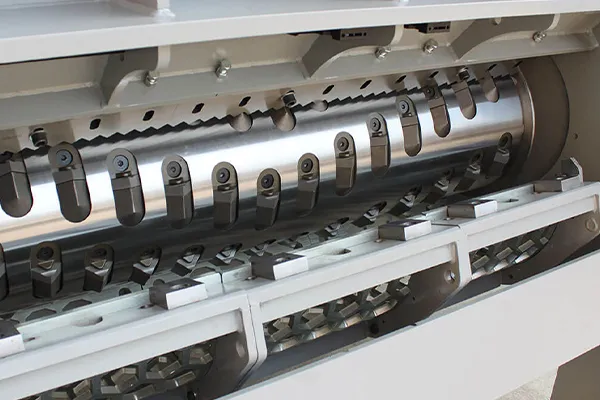

Shafts and blades are key industrial components used in a variety of rotating equipment and mechanical systems. Shafts are usually long, thin metal rods that connect rotating parts, transmit power, and carry loads. Blades are flat or curved structures attached to the shaft and are key components that generate propulsion or fluid flow when rotated. These products are designed with a balance of efficiency and rotary motion in mind and are typically made of high-strength, wear-resistant, and corrosion-resistant materials to ensure long-term reliable operation.

.jpg)

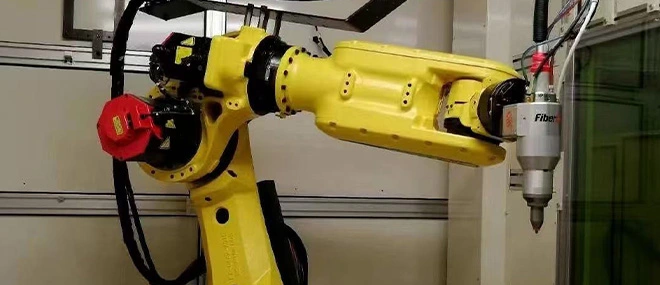

Propulsion systems are key industrial equipment for automation, conveying and handling, and are widely used in logistics, production and warehousing. The main function of the system is to propel objects in a specified direction through mechanical or electrical devices to achieve fast and accurate material transportation and processing. The design of a propulsion system can include various components such as transmissions, guides, sensors and control systems. These components work together to enable the system to operate efficiently in different environments and application scenarios.

.jpg)

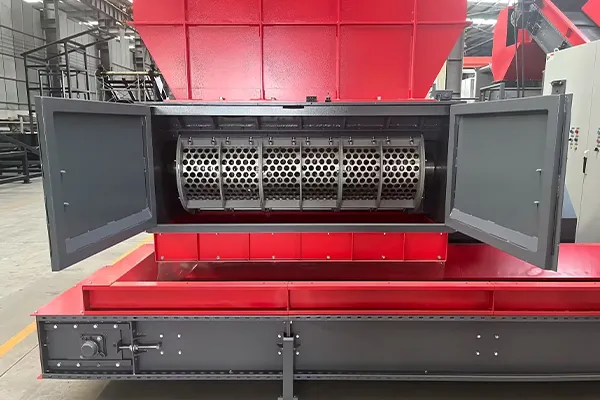

Shred effect of Heavy Duty Single Shaft Shredder

Product Parameters of Heavy Duty Single Shaft Shredder

| Model | FTSS-600 | FTSS-800 | FTSS-1000 | FTSS-1200 |

| Dimensions (mm) | 1780*1290*1690 | 2670*1760*2090 | 2670*1960*2090 | 2670*2500*2090 |

| Hopper Opening (mm) | 1200*1090 | 1500*1430 | 1420*1700 | 1420*1900 |

| Discharging Height (mm) | 480 | 560 | 560 | 560 |

| Rotation Size (mm) | 225 | 285 | 395 | 395 |

| Speed(rpm) | 80 | 80 | 80 | 80 |

| Number of Knives (PVC) | 23+4 | 35+4 | 45+4 | 55+4 |

| Number of Fixed Knives (PVC) | 2+2 | 2+2 | 2+2 | 2+2 |

| Working Diameter (mm) | 600 | 800 | 1000 | 1200 |

| Hopper Volume (L) | 760 | 1500 | 1760 | 2030 |

| Screen Size (mm) | 40 | 40 | 40 | 40 |

| Main Power(kw) | 18.5 | 37 | 45 | 55 |

| Hydraulic Power(kw) | 2.5 | 3.75 | 3.75 | 5.5 |

| Weight (kg) | About 1750 | about 4200 | About 4250 | About 5050 |

Product Actual Pictures of Heavy Duty Single Shaft Shredder

.jpg)

English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español русский

русский Türkçe

Türkçe português

português العربية

العربية Polska

Polska हिंदी

हिंदी Indonesia

Indonesia

.jpg)

.jpg)

.jpg)

.jpg)