When investing in a CNC panel bender, manufacturers and processors face the challenge of choosing a machine that not only meets production needs but also maximizes efficiency. With the growing demand for precision metal bending, it is crucial to focus on key features that ensure high performance, long life, and cost-effectiveness. This article will explore the five most important aspects to consider when purchasing a CNC panel bender.

Precision and Accuracy

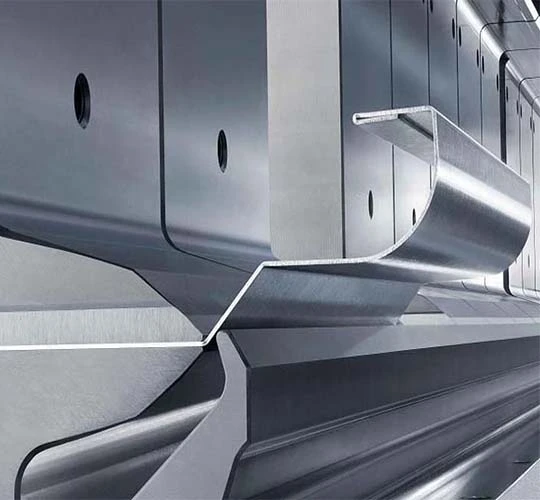

One of the first factors to consider when purchasing a CNC panel bender is its precision and accuracy. A CNC (Computer Numerical Control) panel bender should be able to consistently deliver precise bending results, minimizing the risk of human error, and improving the quality of the finished product. This is particularly important in industries such as aerospace, automotive, and electronics, where even the slightest measurement deviation can lead to product failure.

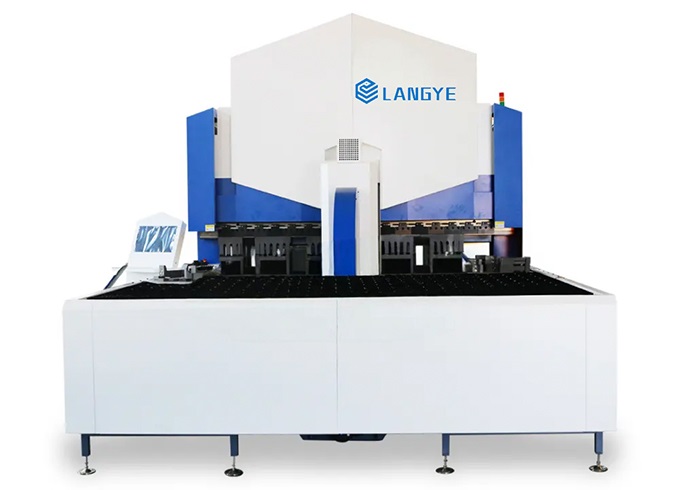

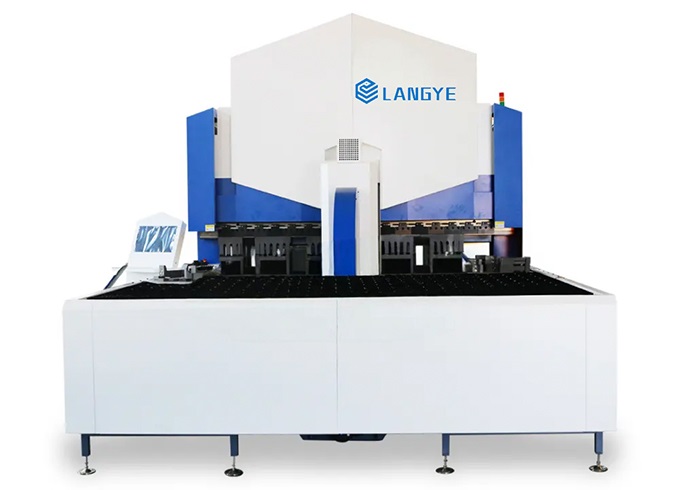

LANGYE excels in precision by designing CNC panel benders that incorporate advanced technology to ensure that every bend meets the strictest tolerance requirements. When considering different models, be sure to inquire about the machine's tolerance specifications.

Automation Features

The level of automation in a CNC panel bender significantly impacts operational efficiency. An automatic panel bender can reduce manual intervention, allowing operators to focus more on critical tasks. Automation not only speeds up production but also lowers labor costs, minimizes errors, and enhances overall productivity.

When choosing, look for machines with automation features such as automatic tool changers, automatic loading and unloading systems, and real-time monitoring. LANGYE's CNC panel benders are equipped with these automation features, allowing manufacturers to achieve greater flexibility and consistency in the production process.

Flexibility and Versatility of the Machine

The flexibility of a CNC panel bender is crucial, as different projects require different bending angles, materials, and sizes. The machine should be able to handle sheets of various thicknesses and adapt to different types of bends, such as single bends or multiple bends.

When selecting a machine, check whether there are options to easily adjust bending parameters to meet different application needs. LANGYE's CNC panel benders are designed to accommodate a wide range of materials, including stainless steel, aluminum alloy, and carbon steel, and can handle both large and small batch production without compromising performance.

User-Friendly Interface and Software Compatibility

The simplicity of operation is another key factor. A CNC panel bender with a user-friendly interface can greatly reduce the learning curve for operators and improve the overall efficiency of the machine. Most modern CNC machines come with intuitive software that allows for easy programming, setup, and control.

Before purchasing, ensure that the machine's software is compatible with your existing systems and check for features such as touch-screen controls, real-time diagnostics, and integration with CAD/CAM software. LANGYE's CNC panel benders come with advanced user interfaces that make programming simple and can seamlessly integrate into existing workflows. The software is designed to be intuitive, allowing even beginners to quickly get up to speed, thereby reducing training time and increasing productivity.

Machine Quality and Maintenance

Durability is an important consideration when selecting a CNC panel bender. Since these machines are designed for high-volume production, they must withstand continuous operation wear and tear. High-quality construction materials, robust structure, and reliable components can ensure that the machine remains efficient even with prolonged use.

Maintenance is another crucial aspect. Easy-to-maintain machines with readily replaceable parts and regular maintenance schedules can save time and costs in the long run. LANGYE's CNC panel benders are designed with durable materials and modular components, making maintenance more convenient and cost-effective. Additionally, LANGYE provides strong after-sales service and technical support to ensure your machine stays in optimal condition.

Investing in a CNC panel bender is a significant decision, requiring careful consideration of key features to ensure you get the best return on your investment. Precision, automation, flexibility, user-friendly interface, and durability are five key factors to focus on when choosing a machine that meets your needs.

As one of the leading panel bender manufacturers, LANGYE offers solutions that excel in all aspects, helping to improve production efficiency and reduce operational costs. Whether you are upgrading existing equipment or purchasing your first CNC panel bender, thoroughly evaluate these features to ensure optimal machine performance and long-term stability.

English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español русский

русский Türkçe

Türkçe português

português العربية

العربية Polska

Polska हिंदी

हिंदी Indonesia

Indonesia