Laser cutting quality is paramount for achieving success in industries such as automotive, aerospace, and metal fabrication, where precise and clean cuts are essential for maintaining high production standards. This guide explores the critical factors that influence laser cutting quality and explains how advanced fiber laser cutting machines are engineered to meet and exceed these demands, delivering exceptional results across diverse applications.

Understanding Laser Cutting Quality

Defining Laser Cutting Quality

Laser cutting quality is determined by several key attributes that ensure the accuracy, smoothness, and reliability of cuts. Precision refers to the ability to produce cuts that align precisely with specified dimensions. Edge quality focuses on the smoothness and finish of cut edges, which should be free of burrs or roughness for a polished appearance. Consistency ensures uniform cuts across multiple parts, a critical factor for high-volume production. Minimizing the heat-affected zone (HAZ) is also essential, as it preserves the material's properties by reducing thermal impact around the cut area, maintaining structural integrity and performance.

Significance Across Industries

High-quality laser cutting is vital for industries with stringent requirements. In automotive manufacturing, precise cuts ensure components fit seamlessly, enhancing vehicle safety and performance. Aerospace applications demand flawless cuts for lightweight, durable parts, while metal fabrication relies on clean edges for both aesthetic and functional purposes. Understanding these quality factors enables manufacturers to meet industry standards and achieve superior outcomes.

Factors Influencing Fiber Laser Cutting Quality

Laser Power and Stability

The power level of a laser significantly impacts its ability to cut through various material thicknesses effectively. Fiber laser cutting machines equipped with high-power lasers can handle a wide range of materials, from thin sheets to thick plates, ensuring versatility. Stable power output is crucial for uniform cuts and minimizing defects. Advanced machines are designed to maintain consistent power levels throughout the cutting process, resulting in reliable and high-quality outcomes.

Beam Quality

To achieve sharp, accurate cuts, a properly focused laser beam is crucial. Advanced optical systems in fiber laser cutting machines maintain sharp beam focus, enabling accurate cutting with minimal deviation. The beam mode, which determines the distribution of laser energy, affects edge smoothness. Machines engineered to produce high-quality beam modes ensure superior edge quality and a professional finish on every cut.

Cutting Speed and Feed Rate

Optimizing cutting speed is critical for balancing quality and efficiency, as it varies based on material type and thickness. Adjustable cutting speeds allow fine-tuning for optimal results across different materials. The feed rate, or the speed at which material is fed into the laser beam, also influences cut quality. Precise control over feed rates ensures consistent, clean cuts, reducing the risk of imperfections and enhancing overall performance.

Assist Gas and Nozzle Design

The choice of assist gas—such as oxygen, nitrogen, or air—and its pressure plays a pivotal role in the cutting process. Systems in fiber laser cutting machines enable selection of the appropriate gas type and adjustment of pressure settings to suit specific materials and cutting requirements. The nozzle's design and condition affect gas flow quality, which directly impacts cut precision. High-quality nozzles, engineered for optimal gas delivery, minimize contamination and ensure smooth, high-quality cuts.

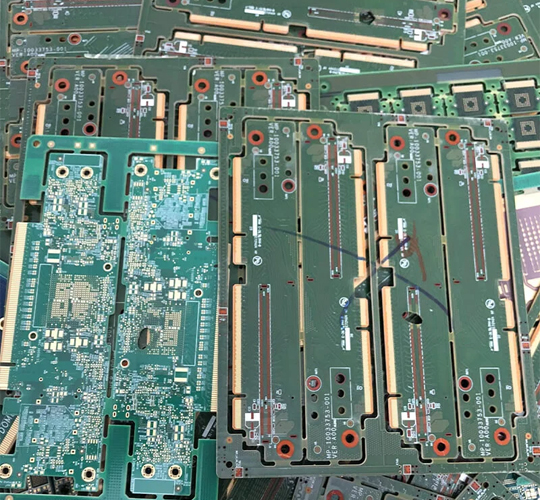

Material Properties

Material type and thickness significantly influence laser cutting quality. Different materials, such as metals or non-metals, respond uniquely to laser cutting, requiring tailored settings for optimal results. Versatile machines can cut a wide range of materials with precision. Material thickness affects the necessary laser power and cutting speed, and machines designed to accommodate various thicknesses deliver clean and accurate cuts regardless of the material's dimensions.

How Fiber Laser Cutting Machines Meet Quality Demands

Advanced Laser Technology

Fiber laser cutting machines incorporate cutting-edge technology, ensuring high power, stability, and exceptional beam quality. This enables precise and efficient cutting across diverse materials and thicknesses, meeting the demands of challenging applications. Advanced fiber lasers deliver consistent performance and superior cut quality, making them suitable for a wide range of industrial needs.

Precision Optics and Control Systems

Precision optics and sophisticated control systems maintain accurate beam focus and optimize cutting parameters. This results in exceptional edge quality and minimal heat-affected zones, preserving material integrity. Control systems allow real-time adjustments, ensuring adaptability to varying conditions for consistently high-quality cuts.

Flexible and Customizable Settings

To accommodate diverse project requirements, fiber laser cutting machines offer customizable settings for cutting speed, feed rate, assist gas type, and pressure. This flexibility allows tailoring of performance to specific materials and applications, achieving optimal results with ease. Whether cutting thin aluminum or thick steel, these machines provide the versatility needed for top-tier performance.

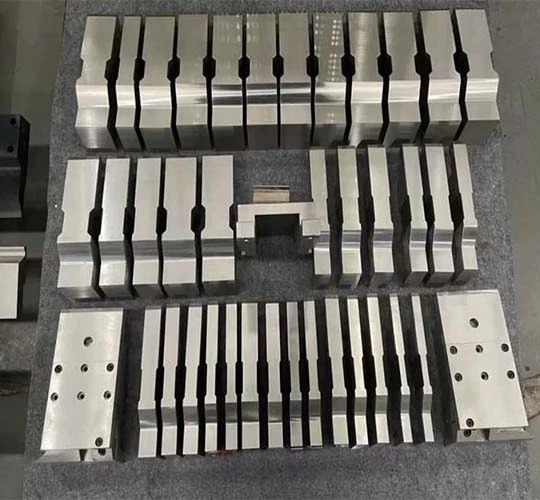

Durable Construction for Long-Term Reliability

Constructed with high-quality materials and components, fiber laser cutting machines are built for durability and reliability. This robust design ensures consistent performance over extended periods, with minimal maintenance requirements. Machines engineered for longevity provide sustained cutting quality and operational efficiency.

Comprehensive Support and Training

Comprehensive support and training are provided to maximize the capabilities of fiber laser cutting machines. From initial setup to ongoing maintenance, expert guidance ensures optimal performance. This support enables achievement of the highest standards of cutting quality, enhancing productivity and operational confidence.

Achieving Superior Laser Cutting Standards

High-quality laser cutting is essential for industries reliant on precision and consistency. Fiber laser cutting machines are meticulously designed to deliver outstanding precision, smooth edges, and reliable performance. By addressing critical factors such as laser power, beam quality, cutting speed, assist gas, and material properties, these machines meet the diverse needs of modern manufacturing. Investing in advanced fiber laser cutting technology ensures unparalleled quality, efficiency, and versatility in production processes.

English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español русский

русский Türkçe

Türkçe português

português العربية

العربية Polska

Polska हिंदी

हिंदी Indonesia

Indonesia