Enhancing Operator Control

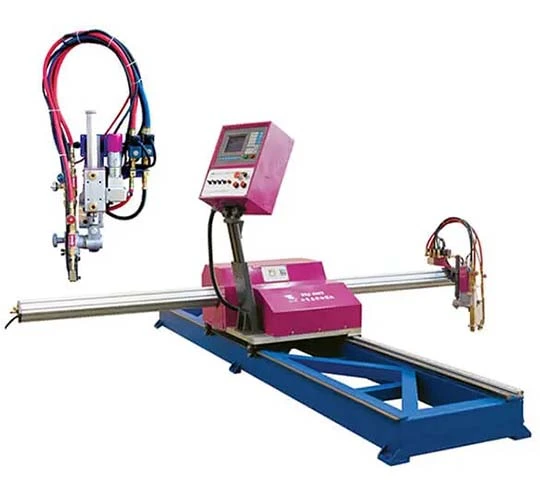

One of the most notable advantages of a press brake foot pedal is the control it offers to machine operators. When working with sheet metal, precision and timing are critical to achieving accurate bends without compromising material quality. By utilizing a foot pedal, operators can keep both hands free to properly position the workpiece, ensuring that it remains stable during the bending process. This hands-free operation minimizes errors and maximizes productivity, allowing workers to maintain focus on alignment and safety. The responsiveness of a well-designed press brake foot pedal ensures smooth activation, making it easier for operators to achieve the exact pressure and angle required for each bend.

Improving Workflow Efficiency

In modern sheet metal fabrication, efficiency is just as important as accuracy. The press brake foot pedal plays a vital role in streamlining workflow by enabling operators to control the press brake without interrupting their handling of materials. This seamless integration reduces downtime between operations, as workers do not need to constantly shift positions to engage machine functions. For high-volume production environments, this feature significantly increases throughput, helping manufacturers meet demanding schedules while maintaining consistent quality. The ergonomic design of foot pedals also reduces physical strain on operators, contributing to longer, more comfortable working sessions that support higher overall output.

Supporting Precision and Safety

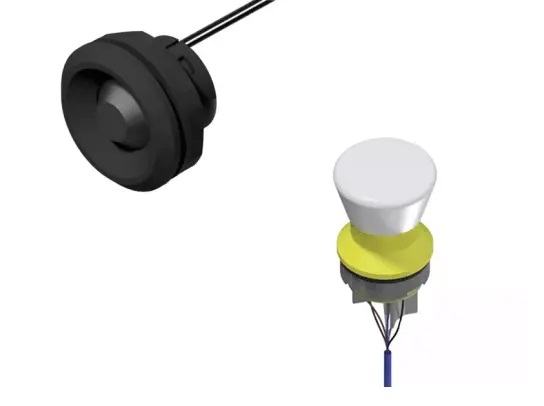

Safety is always a top priority when operating heavy-duty equipment such as press brakes. The press brake foot pedal contributes to a safer working environment by giving operators precise control over the machine’s movement. Many advanced foot pedals include safety mechanisms such as two-step activation, which requires deliberate operator input to engage the press, reducing the risk of accidental starts. Additionally, the ability to stop machine motion instantly with the foot pedal enhances overall safety by providing operators with immediate control in case of misalignment or unexpected issues. This combination of precision and safety is crucial in preventing material waste and protecting both workers and equipment.

Versatility Across Applications

The use of a press brake foot pedal is not limited to a single type of bending operation. Its adaptability makes it valuable in a wide variety of applications, from simple single bends to complex multi-step forming tasks. Operators can program the machine to respond to different pedal actions, such as half-press for positioning and full-press for bending, enabling greater versatility in managing workflows. This functionality supports industries that rely on press brakes for diverse fabrication needs, including automotive, aerospace, construction, and appliance manufacturing. By integrating a reliable foot pedal, businesses can expand the range of products and components they produce without compromising efficiency or accuracy.

Long-Term Productivity Benefits

Beyond immediate efficiency and safety gains, the press brake foot pedal also contributes to long-term productivity improvements. By reducing the risk of operator fatigue and enhancing ergonomic conditions, foot pedals help maintain consistent performance across multiple shifts. Their durability ensures reliable operation even under heavy use, minimizing the need for frequent replacements or repairs. Over time, these advantages translate into lower operating costs, less downtime, and more consistent production quality. In an industry where precision and output directly influence competitiveness, the benefits of a high-quality press brake foot pedal extend far beyond the initial investment, making it a crucial accessory for maximizing the potential of press brake machines.

English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español русский

русский Türkçe

Türkçe português

português العربية

العربية Polska

Polska हिंदी

हिंदी Indonesia

Indonesia