This guide provides a detailed exploration of single shaft shredders, offering insights into their functionality, applications, and benefits. Whether you're an industry professional or simply curious about these powerful machines, this article covers everything from their types and components to selection tips and maintenance practices, equipping you with the knowledge to understand and utilize these versatile tools effectively.

Key Takeaways

Single shaft shredders are highly adaptable machines capable of processing a diverse array of materials, such as plastics, wood, metal scrap, tires, and hazardous waste. Available in various forms, including rotary shredders, granulator shredders, and industrial models, these machines are equipped with robust motors, durable shredding blades, and specialized chambers designed to handle different materials efficiently. Their advanced safety features ensure secure operation, while their versatility supports applications in waste management and recycling, contributing to environmental sustainability by facilitating easier material processing and reducing landfill waste.

Types of Single Shaft Shredders

Single shaft shredders come in several varieties, each tailored to specific materials and applications, utilizing distinct shredding techniques to break down waste effectively. Rotary shredders, for instance, employ rotating blades to chop materials into smaller pieces, making them ideal for recycling plastics, rubber, and wood. Granulator shredders combine cutting and grinding to produce fine particles, which is particularly useful in the plastic and paper industries where precise particle sizes are essential for production. For heavy-duty tasks, single shaft industrial shredders excel, processing large volumes of tough materials like metal scrap, tires, and bulky plastics with a single shaft equipped with multiple blades for high-throughput shredding. These shredders play a critical role in waste management, recycling, and manufacturing, efficiently handling materials such as plastics, paper, wood, rubber, and hazardous waste to support a greener environment.

Key Features and Components

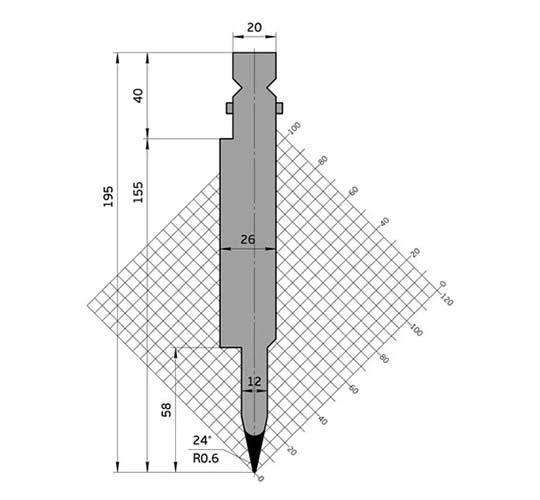

Single shaft shredders are engineered with components that enhance their efficiency and reliability across various applications. A powerful motor drives the shredding blades, providing the strength needed to process materials like plastics, wood, and metals effectively. These blades, crafted from high-quality materials, ensure durability and resilience against the demands of shredding tough substances. The shredding chamber is designed to accommodate various material types and sizes, optimizing the shredding process. A user-friendly control panel allows operators to monitor and manage the machine's performance with ease. Additionally, advanced safety features, such as automatic overload protection and emergency stop buttons, safeguard both the operator and the machine, ensuring reliable and secure operation.

Advantages of Single Shaft Shredders

Single shaft shredders offer significant benefits, including their ability to process a wide range of materials, from soft plastics to hard metals, with high efficiency and productivity. Their robust motors and cutting systems enable rapid reduction of bulky items into manageable pieces, making them suitable for high-volume operations. The versatility of these shredders allows them to handle diverse materials without compromising performance, reducing the need for multiple machines and saving both space and costs. Environmentally, they support recycling and waste management by breaking materials into smaller, recyclable pieces, which minimizes landfill waste and promotes resource conservation through material reuse and repurposing.

How to Select the Right Single Shaft Shredder

Selecting the appropriate single shaft shredder involves evaluating several key factors to ensure it meets your specific needs. Consider the types of materials you plan to process, as different shredders are optimized for specific materials like plastics, wood, or paper. The desired output size of the shredded material is another critical consideration, as some machines offer adjustable settings to achieve various particle sizes. Additionally, ensure the shredder's power requirements align with your facility's available power supply. These versatile machines are widely used in recycling, waste management, and industrial applications, making them a valuable asset when chosen thoughtfully based on material type, output size, and power compatibility.

Maintenance and Safety Guidelines for Single Shaft Shredders

To maintain the efficiency and safety of a single shaft shredder, regular inspection and cleaning are essential. Routinely check the machine for signs of wear or damage, replacing loose or worn-out parts as needed, and clean it to remove debris that could impair performance. Proper lubrication of moving parts, such as blades and bearings, is crucial to minimize friction and prevent premature wear, following the manufacturer's recommendations. Adhering to safety guidelines is equally important—operators should wear protective gear like safety goggles and gloves, keep hands and clothing clear of the feeding area, and avoid overloading the machine or processing unsuitable materials to ensure safe and effective operation.

Conclusion

Single shaft shredders are indispensable tools across industries, delivering efficient and powerful performance in processing materials like plastics, tires, and metals. Their key components, such as robust rotors and cutting systems, ensure optimal shredding results, while their high throughput and low maintenance needs make them a cost-effective solution for waste management. By adhering to proper maintenance and safety practices, users can extend the lifespan of these shredders and ensure safe, reliable operation, making them a valuable asset for sustainable material processing.

English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español русский

русский Türkçe

Türkçe português

português العربية

العربية Polska

Polska हिंदी

हिंदी Indonesia

Indonesia