Metal shredders are critical tools in the scrap metal recycling industry, enabling the efficient processing of both ferrous and non-ferrous metals for reuse. These machines reduce bulky scrap into manageable pieces, facilitating transportation, sorting, and recycling. Beyond preparing metal for steel mills, shredders also serve industries requiring secure destruction of materials. This guide explores the operation of metal shredders, their necessity in recycling, the fate of shredded metal, and their contribution to a circular economy, highlighting their role in sustainable metal processing.

How Scrap Metal Shredders Operate

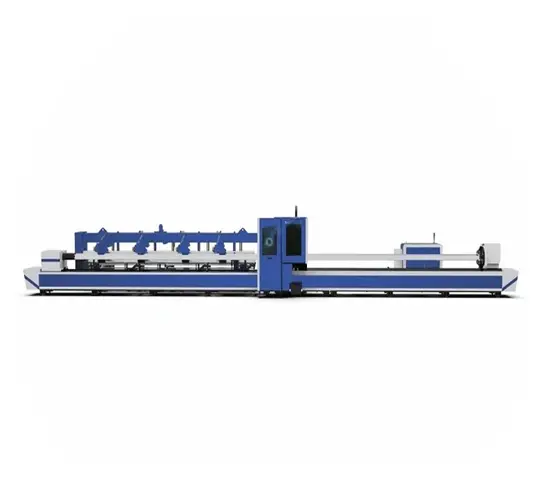

Scrap metal shredders are designed to break down large pieces of metal into smaller, transportable fragments. Available in various sizes, these machines range from compact units for shredding small items like cans to massive systems capable of processing thousands of tons of metal daily, including entire vehicles, bulk drums, and diverse scrap types. Shredders feature different cutting systems, such as horizontal or vertical shafts, and can have single, double, or multiple shafts equipped with blades of varying claw thicknesses tailored to the material. Typically, scrap metal recycling employs slow-speed, high-torque shredders, which effectively handle large metal pieces. In industrial applications, scrap like crushed vehicles is fed into the shredder through a feeder pipe, where heavy-duty hammers rotate to fragment the metal. Magnets then separate ferrous from non-ferrous materials, and conveyor belts transport the shredded output into distinct piles for further sorting, streamlining the recycling process.

Why Shredding Scrap Metal Is Essential

Shredding is a vital step in scrap metal recycling due to the impracticality of transporting bulky items in their original form. For instance, an old vehicle occupies significant space, but once crushed and shredded, it becomes compact and easier to handle. Shredding significantly reduces the volume of scrap, making it more manageable for storage and transportation. Additionally, the process facilitates the separation of ferrous metals, like steel, from non-ferrous metals, such as aluminum, and non-metal materials, including rubber, plastics, and fabrics. This separation maximizes the value extracted from scrap by enabling efficient recycling of each material type, ensuring metals are prepared for further processing while non-metals are diverted from landfills.

What Happens to Shredded Scrap Metal

After shredding, the reduced metal is transported to facilities for further processing. Non-ferrous metals and non-metal materials, such as plastics, glass, and textiles, are separated during shredding and sent for specialized recycling, reducing landfill waste. Ferrous metals are typically exported to steel mills, where they are melted in large furnaces. To ensure high quality, the molten metal undergoes purification, often through electrolysis, which uses an electric current to remove contaminants. Once purified, the metal is cooled and solidified into raw material ready for manufacturing new products. This process, supported by partnerships with ports for global export, underscores the far-reaching impact of scrap metal recycling.

Contribution to a Circular Economy

Metal shredders play a significant role in promoting a circular economy by enabling high-capacity processing of scrap metal. Without shredders, handling bulky scrap at scale would be unfeasible, limiting the ability to meet global demand for recycled metal. Shredding reduces scrap to manageable volumes, facilitating efficient recycling and resource conservation. Approximately 40% of new metal used today originates from recycled sources, and increasing this percentage is crucial for preserving natural resources. By separating non-metal and non-ferrous materials during shredding, these machines further reduce landfill waste, supporting sustainable waste management. Through their capacity to process and recycle metal efficiently, shredders contribute significantly to environmental preservation and the sustainable production of new materials.

The Vital Role of Metal Shredders

Metal shredders are indispensable in the scrap metal recycling industry, transforming bulky waste into compact, recyclable materials. Their ability to reduce metal size, separate ferrous and non-ferrous components, and prepare materials for further processing enhances recycling efficiency and supports global sustainability efforts. By facilitating the reuse of metals and diverting non-metal materials from landfills, shredders play a crucial role in advancing a circular economy, ensuring resources are conserved and environmental impact is minimized.

English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español русский

русский Türkçe

Türkçe português

português العربية

العربية Polska

Polska हिंदी

हिंदी Indonesia

Indonesia