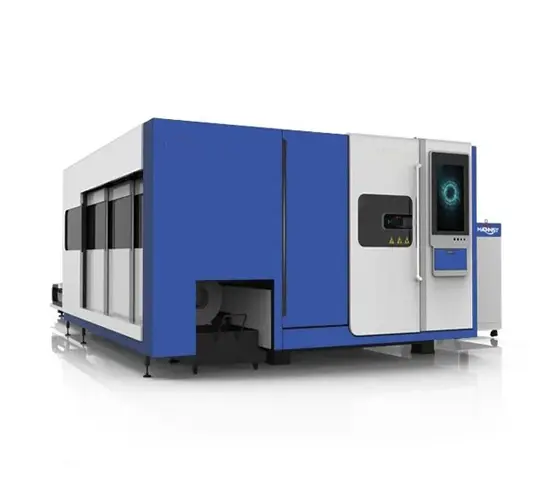

Laser cutting is an advanced industrial technology designed to precisely and efficiently shape metals and other materials for various manufacturing applications. By utilizing a high-powered laser, this process burns, melts, or vaporizes unwanted material, resulting in a smooth, high-quality edge finish. The technique is highly valued for its ability to produce accurate cuts, making it a preferred choice for creating intricate designs and components across industries. Its efficiency and precision have revolutionized manufacturing, enabling the production of complex parts with minimal waste and exceptional surface quality.

Accuracy of Laser Cutting

Laser cutting stands out as a highly efficient, safe, and accurate method compared to traditional sheet metal cutting techniques. The process is driven by computer-operated programs that guide the laser to cut materials within a tight accuracy range. Often integrated with CAD software, laser cutting ensures precise execution of complex designs. The laser beam can focus on an area as small as approximately 25 microns, roughly a quarter of the width of a human hair, allowing for exceptional detail. Additionally, the cut width can be as narrow as less than 0.001 inches, and dimensional accuracy typically reaches about ±0.0005 inches. This level of precision makes laser cutting ideal for applications requiring exact specifications and consistent results.

Why Laser Cutting Is Accurate

The remarkable accuracy of laser cutting stems from its computer-guided operation, which enhances both precision and safety. The technology employs a consistent stream of coherent photons, synchronized into a steady, intense energy beam that meticulously slices through materials like metal and glass. This focused beam ensures clean, precise cuts. Laser cutting also features low tolerances, meaning the resulting cuts have minimal deviation from the intended design, offering faster and more consistent results than manual methods. Modern laser cutters use fiber optic lenses to guide and control the laser beam, ensuring clear and direct positioning for enhanced precision. Unlike traditional methods, laser cutting avoids direct contact with the material, using heat to make cuts, which reduces damage to surrounding areas and ensures consistent outcomes. The technology's ability to handle highly intricate and detailed work with unmatched control and fidelity makes it ideal for complex projects requiring low tolerances.

Factors Affecting Laser Cutting Accuracy

Achieving optimal precision in laser cutting depends on several key factors. The type of material being cut significantly impacts accuracy; smoother or thinner materials generally allow for more precise cuts, and appropriate machine settings must be tailored to the material's composition. The laser beam's spot size is another critical factor; a smaller spot size produces more meticulous cuts compared to wider ones, enabling finer details. Laser power level also plays a role—higher-intensity beams are better suited for cutting thicker materials, ensuring flawless, even results. Additionally, the stability and accuracy of the workbench are crucial. A poorly stabilized workbench can introduce vibrations, reducing the fidelity of the cut and deviating from the original design. By carefully managing these factors, operators can maximize the precision of laser cutting processes.

Benefits and Applications of Laser Cutting

Laser cutting offers significant advantages over traditional cutting methods, combining extreme precision with efficiency. Its low lead times, reduced material waste, and lower operational costs make it a cost-effective solution for manufacturing. The technology's unparalleled accuracy and low tolerance levels enable it to handle even the most complex and intricate jobs, from detailed metalwork to high-precision components. This makes laser cutting indispensable in industries such as automotive, aerospace, and electronics, where exacting standards are critical. Partnering with a provider offering state-of-the-art laser cutting services ensures access to world-class quality and competitive pricing. Expert teams can deliver tailored solutions, addressing specific project needs and providing high-quality results for demanding applications.

English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español русский

русский Türkçe

Türkçe português

português العربية

العربية Polska

Polska हिंदी

हिंदी Indonesia

Indonesia