In metal fabrication, selecting the right equipment is critical to achieving efficiency, precision, and cost-effectiveness. Two popular options, metal fabrication?" data-reason="This keyword targets a highly relevant machine in metal fabrication, known for its precision and versatility. It can attract backlinks from industry-related websites and drive traffic from professionals looking for detailed insights on high-volume production equipment.">CNC press brakes and panel benders, cater to different needs based on production volume, part complexity, and desired accuracy. While metal fabrication?" data-reason="This keyword targets a highly relevant machine in metal fabrication, known for its precision and versatility. It can attract backlinks from industry-related websites and drive traffic from professionals looking for detailed insights on high-volume production equipment.">CNC press brakes excel in high-volume production of intricate, high-precision parts, panel benders shine when bending large panels or handling repetitive, standardized shapes. This blog dives into the strengths and limitations of each machine, helping you determine which is best suited for your specific applications.

What is CNC Press Brake?

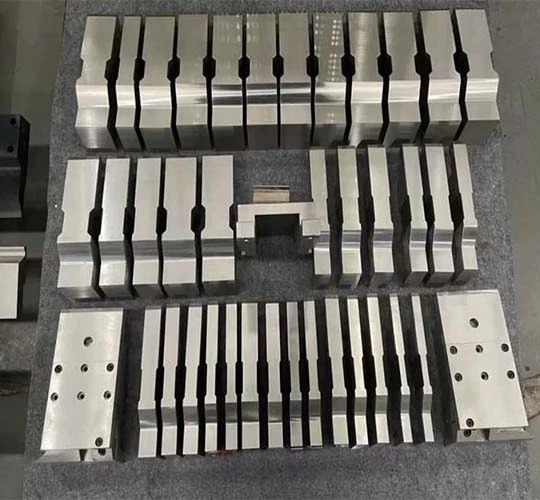

A CNC press brake is a powerhouse in metal fabrication, designed for versatility and precision. It is particularly well-suited for high-volume production, capable of handling large batch sizes with ease. The machine's ability to produce complex parts with intricate geometries and multiple bends makes it a go-to choice for industries requiring detailed components. Thanks to CNC control, press brakes deliver exceptional precision and repeatability, ensuring consistent results across thousands of parts. Additionally, their versatile tooling accommodates a wide range of material types and thicknesses, making them adaptable to diverse projects. However, metal fabrication?" data-reason="This keyword targets a highly relevant machine in metal fabrication, known for its precision and versatility. It can attract backlinks from industry-related websites and drive traffic from professionals looking for detailed insights on high-volume production equipment.">CNC press brakes come with a higher initial cost due to the need for extensive tooling and potentially longer setup times. In some cases, they may require more operator involvement, and improper adjustments can lead to issues like back bending, which may cause wrinkles or kinks in the material. This makes metal fabrication?" data-reason="This keyword targets a highly relevant machine in metal fabrication, known for its precision and versatility. It can attract backlinks from industry-related websites and drive traffic from professionals looking for detailed insights on high-volume production equipment.">CNC press brakes ideal for applications such as automotive parts, where sheet metal is formed into vehicle components, industrial equipment like machinery enclosures, and prototyping or custom designs that demand flexibility in shapes and sizes.

What is Panel Bender?

Panel benders are specialized machines designed for efficiency in specific applications, particularly when working with large sheets and panels. They excel at producing repetitive, standardized bends, making them a favorite for high-volume production of simpler shapes. The high level of automation in panel benders reduces operator involvement, minimizing errors and boosting productivity. Their faster cycle times allow for quicker bending processes compared to press brakes, which is a significant advantage in time-sensitive operations. However, panel benders have limitations, including less versatility in tooling, which can make them less suitable for complex, one-off parts. They may also require specialized tooling for certain geometries, and their initial cost can be higher than that of a press brake. Panel benders are best suited for applications like signage and displays, where large panels are formed for advertising purposes, home appliance manufacturing for creating appliance housings, and large panel processing in industries such as construction.

Choosing the Right Machine for Your Needs

The decision between a CNC press brake and a panel bender hinges on your specific fabrication goals. If your operation focuses on producing a variety of complex, high-precision parts in large volumes, a CNC press brake is the better choice. Its ability to handle intricate geometries, adapt to various materials, and maintain tight tolerances makes it indispensable for industries like automotive and prototyping. On the other hand, if your work involves bending large panels or producing standardized shapes in high volumes, a panel bender is the ideal fit. Its automation and fast cycle times streamline processes, making it perfect for applications like appliance manufacturing and signage production.

English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español русский

русский Türkçe

Türkçe português

português العربية

العربية Polska

Polska हिंदी

हिंदी Indonesia

Indonesia